Metal Polishers Writtle UK

Metal Polishers Writtle: Your hunt for local metal polishers should really commence below as you can effectively employ the versatile map to acquire a listed metal polisher in the Writtle, Essex locality. Any time no metal polishers display on the map, try the zoom out navigation button.

Writtle Metal Polishers: Choosing a tradesman by using the top listings in search engines on the world wide web, might not in many cases be the right option, because these are in many cases not really local metal polishers, but typically country wide enterprises. You after all need metal polishers in the vicinity of Writtle, Essex.

Are the glass windows appearing a tad grimy? No doubt you'll be trying to find a dependable metal polisher who you can trust in to complete the work.

Picking a polishing company using the highest results in search engines on the internet, could possibly not always be the correct option, since these are often not in fact localized metal polishers, but in most cases countrywide businesses.

Responsible polishing companies however, don't seem to be that tricky to identify, you will easily manage to discover one in your area.

Asking people in your local area, is a fantastic approach to finding a first-rate metal polishing firm, referrals by people who've utilised them in the past might deliver effective tradesmen.

It is easy to additionally obtain totally free quotes and browse previous homeowners ratings and reports on one of the few various tradesmen referral sites such as Trustatrader, Rated People, Bark, CheckaTrade or My Builder.

To obtain companies, businesses and skills not listed on this category of online websites, you could well look at one or some of these:

Thomson Local, Approved Business, Brown Book, My Local Services, City Listings, BizzBuzz, Wampit, Business Magnet, Top Pages, Opendi, Near, Touch Local, 118 118, 192, Scoot, Local Data Search, 1st Directory, City Local, My Sheriff, Hotfrog, Tipped, Gomy, Places Locally, UK Internet Directory, U Find Us, Fyple, or other local business directories.

Are the glass windows appearing a tad grimy? No doubt you'll be trying to find a dependable metal polisher who you can trust in to complete the work.

Picking a polishing company using the highest results in search engines on the internet, could possibly not always be the correct option, since these are often not in fact localized metal polishers, but in most cases countrywide businesses.

Responsible polishing companies however, don't seem to be that tricky to identify, you will easily manage to discover one in your area.

Asking people in your local area, is a fantastic approach to finding a first-rate metal polishing firm, referrals by people who've utilised them in the past might deliver effective tradesmen.

It is easy to additionally obtain totally free quotes and browse previous homeowners ratings and reports on one of the few various tradesmen referral sites such as Trustatrader, Rated People, Bark, CheckaTrade or My Builder.

To obtain companies, businesses and skills not listed on this category of online websites, you could well look at one or some of these:

Thomson Local, Approved Business, Brown Book, My Local Services, City Listings, BizzBuzz, Wampit, Business Magnet, Top Pages, Opendi, Near, Touch Local, 118 118, 192, Scoot, Local Data Search, 1st Directory, City Local, My Sheriff, Hotfrog, Tipped, Gomy, Places Locally, UK Internet Directory, U Find Us, Fyple, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Writtle include: mirror polishes, circle finishes, metal fabrication, aluminium metal polishing, on site polishing services, automotive polishing, titanium polishing, polishing bronze, vintage polishing, dull and satin polishing, polishing alloy wheels, specialist angle polishing, custom metal polishing, reflective finishes, same day polishing, polishing brass, industrial and commercial polishing, commercial and super bright polishing, sheet metal polishing, aluminium polishing, metal finishing, metal polishing and finishing, metal polishing motorcycle parts, metal polishing aluminium, polishing iron, metal polishing services, duplex finishes, decorative polishing, motorcycle metal polishing, industrial polishing, grained finishes.

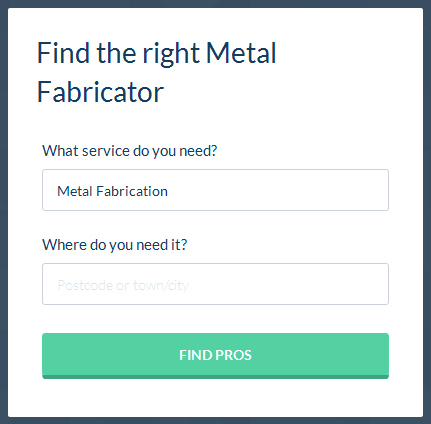

Find Writtle Metalworkers With Bark

| Quotes From a Metalworker in Writtle |  |

Do-it-Yourself Metal Polishing Tips

A Summary of Metal Finishing - Most of the time, metal polishing is required for aesthetic reasons and clean-room situations. It is one of the most accepted methods due to its usefulness in intensifying the natural beauty of the product, for example, cookware, motor vehicle parts or motorbike parts. Besides that, a great many clean-rooms need a polished finish as a way to reduce the penetrability of the components which could cause debris to collect and contaminate. An illustration of this use would be in a vacuum chamber. There are certainly countless different ways to finish metals, and we can have a look at the various procedures required. Metal can be polished by hand, with purpose built buffing machines, electromechanically or applying chemicals. A finishing paste or compound could be applied, which might contain dolomite, chromium oxide, chalk, limestone, aluminum oxide, tripoli, or iron oxide. Polishing stainless steel, due to its mediocre thermal conductivity, fairly high viscidity, and hardness is among the most time-consuming. On the contrary, merchandise built from non-ferrous metal are much more amenable to polishing, as these require the lower number of operations. Where a high processing quality is not important, quicker pad speeds should be employed. A lower pad speed is applied when a quality mirror finish is demanded. Finishing buffs plastered in paste can be markedly affected by the load on the buffing pad. The level of the pressure on the surface can be elevated within certain limits, however surpassing the perfect degree of force not simply cuts down the quality level of treatment, but additionally degrades performance, can result in wear to the product, plus there is in addition an evident heating up of the items being worked on, due to friction. With thin material, it is increased temperature (and the relating bendability of the material) that can cause parts to distort, warp or buckle. As a rule, it requires a highly trained polisher to add in all of these fundamentals to equally prevent harm to the metal part and to work proficiently. To be able to significantly improve the standard of the resultant surface, the buffing action needs to be implemented with a reduced amount of aggression and not so much pressure so that you might consequently produce a surface that doesn't have any scratches or fine lines left behind by the buffing process, thus arriving at a lovely mirror finish.

Where a high processing quality is not important, quicker pad speeds should be employed. A lower pad speed is applied when a quality mirror finish is demanded. Finishing buffs plastered in paste can be markedly affected by the load on the buffing pad. The level of the pressure on the surface can be elevated within certain limits, however surpassing the perfect degree of force not simply cuts down the quality level of treatment, but additionally degrades performance, can result in wear to the product, plus there is in addition an evident heating up of the items being worked on, due to friction. With thin material, it is increased temperature (and the relating bendability of the material) that can cause parts to distort, warp or buckle. As a rule, it requires a highly trained polisher to add in all of these fundamentals to equally prevent harm to the metal part and to work proficiently. To be able to significantly improve the standard of the resultant surface, the buffing action needs to be implemented with a reduced amount of aggression and not so much pressure so that you might consequently produce a surface that doesn't have any scratches or fine lines left behind by the buffing process, thus arriving at a lovely mirror finish. Also find metal polishers in: Chelmsford , Edney Common, Margaretting, Springfield, Good Easter, Blackmore, Willingale, Widford, Galleywood, Broomfield, Beauchamp Roding, Little Waltham, Great Oxney Green, Roxwell, Ingatestone and areas near to Writtle, Essex. Maybe our advice helped you to find a decent metal polishing contractor.

|

Northamptonshire Metal Polishers |

TOP - Trustworthy Odd Job Man - Inexpensive Garden Clearance - Door Fitters Specialists - Kitchen Worktops Duffield - Door Installation Ventnor - Odd Job Man Exeter