Metal Polishers Wombourne UK

Metal Polishers Wombourne: Your hunt for nearby metal polishers can start below since you can conveniently employ our convenient google map to locate a named metal polisher active in the Wombourne, Staffordshire locality. Try the pan out any time no metal polishers are shown on this map.

Wombourne Metal Polishers: Asking near your local area, is the best option to find a first rate metal polisher, testimonials and referrals by customers who utilized them before really should yield reliable results. You of course are seeking metal polishers somewhere around Wombourne, Staffordshire.

There are numerous techniques you can employ locating a dependable metal polisher, with phone book, local newspapers along with the net, being the most favored.

If you use the internet for a search, just picking out the top metal polisher rankings in an online search engine will not in many cases be the best option because they in many cases will most likely not actually be local metal polishing businesses.

Quality metal polishing businesses though, aren't that difficult to find, you will without difficulty be able to discover one around.

Personal referrals are obviously the most suitable approach to find a professional metal polishing business, so you can ask someone who you know who recurrently makes use of metal polishers.

To find highly recommended professionals in many trades you should use one of the primary tradesmen assessment websites including My Builder, CheckaTrade, Trustatrader or Rated People, when previous homeowners give comments and testimonials.

To obtain businesses, trades and facilities that are not listed on this category of sites, you could well consider one or two of these:

Top Pages, Local Data Search, 2 Find Local, Wampit, Places Locally, City Listings, Opendi, Thomson Local, B2Index, My Sheriff, Yell, City Visitor, 1st Directory, 192, My Local Services, Scoot, Hotfrog, Britaine, Gomy, City Local, 118 118, The Sun Business Directory, 4ni, Yalwa, Yelp, Wahanda, or other local business directories.

There are numerous techniques you can employ locating a dependable metal polisher, with phone book, local newspapers along with the net, being the most favored.

If you use the internet for a search, just picking out the top metal polisher rankings in an online search engine will not in many cases be the best option because they in many cases will most likely not actually be local metal polishing businesses.

Quality metal polishing businesses though, aren't that difficult to find, you will without difficulty be able to discover one around.

Personal referrals are obviously the most suitable approach to find a professional metal polishing business, so you can ask someone who you know who recurrently makes use of metal polishers.

To find highly recommended professionals in many trades you should use one of the primary tradesmen assessment websites including My Builder, CheckaTrade, Trustatrader or Rated People, when previous homeowners give comments and testimonials.

To obtain businesses, trades and facilities that are not listed on this category of sites, you could well consider one or two of these:

Top Pages, Local Data Search, 2 Find Local, Wampit, Places Locally, City Listings, Opendi, Thomson Local, B2Index, My Sheriff, Yell, City Visitor, 1st Directory, 192, My Local Services, Scoot, Hotfrog, Britaine, Gomy, City Local, 118 118, The Sun Business Directory, 4ni, Yalwa, Yelp, Wahanda, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Wombourne include: brushed finishes, decorative polishing, same day polishing, circle finishes, metal polishing and finishing, polishing internal bores, metal fabrication, custom metal polishing, bespoke polishing, automotive polishing, metal polishing motorcycle parts, polishing iron, dull and satin polishing, linear metal polishing, grained finishes, specialist angle polishing, trusted metal polishers, polishing bronze, polishing alloy wheels, quality metal polishing, aluminium polishing, mirror polishes, vintage polishing, polishing copper, metal polishing services, polishing machine parts, commercial polishing, metal polishing aluminium, metal finishing, commercial and super bright polishing, polishing brass.

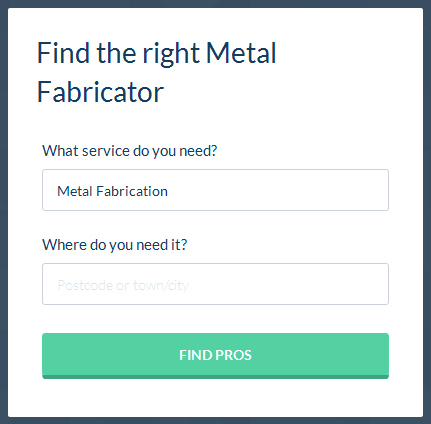

Find Wombourne Metalworkers on Bark

| Search for a Metalworker in Wombourne |  |

Do-it-Yourself Metal Polishing Tips

An Overview of Metal Polishing - Normally, metal polishing is required for appearance and clean-room usage. It's among the most accepted techniques for its use in intensifying the original beauty of the item, for example, motorcycle parts, auto parts or cookware. Aside from that, plenty of clean-rooms desire a shiny finish to reduce the permeability of the metal surfaces which may result in particles to build up and contaminate. An outstanding demonstration of this application could be in vacuum chambers. There are certainly a lot of ways to finish metals, and let us examine examples of the procedures required. Various metals can be finished electromechanically, chemically, manually, or with special buffing machines. A particular buffing compound or paste is generally put into use, that may contain dolomite, aluminum oxide, tripoli, chromium oxide, limestone, chalk, or iron oxide. Finishing stainless steel, due to its below average thermal conductivity, its hardness, and its quite high viscosity is frequently one of the most time-consuming. Opposite of that scenario, things crafted from non-ferrous metal are often more receptive to polishing, simply because these need the minimum number of processes. Whenever a greater processing quality isn't vital, quicker pad speeds should be employed. A lesser pad speed must be used any time a superior mirror finish is demanded. Polishing buffs coated with compound will be dramatically impacted by the forces on the pad. The level of the surface pressure might be amplified within certain limitations, although going beyond the maximum level of load not merely cuts down the quality of the procedure, but in addition can degrade performance, can bring about wear to the part, plus there is also a noticeable heating of the metal being worked on, an outcome of friction. When you are using thinner items, it will be elevated heat (and a relating pliancy of the metal) that can cause components to buckle, twist or distort. In general, it will require a talented polisher to look at every one of these things to equally prevent damage to the metal part and to give good results correctly. To help you radically enhance the standard of the final surface area, the buffing operation needs to be accomplished with a reduced amount of aggression and not so much pressure in order to finally deliver a surface with no scores or marks resulting from the buffing procedure, thus ending up with a lovely mirror finish.

Whenever a greater processing quality isn't vital, quicker pad speeds should be employed. A lesser pad speed must be used any time a superior mirror finish is demanded. Polishing buffs coated with compound will be dramatically impacted by the forces on the pad. The level of the surface pressure might be amplified within certain limitations, although going beyond the maximum level of load not merely cuts down the quality of the procedure, but in addition can degrade performance, can bring about wear to the part, plus there is also a noticeable heating of the metal being worked on, an outcome of friction. When you are using thinner items, it will be elevated heat (and a relating pliancy of the metal) that can cause components to buckle, twist or distort. In general, it will require a talented polisher to look at every one of these things to equally prevent damage to the metal part and to give good results correctly. To help you radically enhance the standard of the final surface area, the buffing operation needs to be accomplished with a reduced amount of aggression and not so much pressure in order to finally deliver a surface with no scores or marks resulting from the buffing procedure, thus ending up with a lovely mirror finish. Also find metal polishers in: Blakeley, Pattingham , Perton, Trysull, Himley, Stirchley, Sedgley, Penn, Castlecroft, Swindon, Gornalwood, Bobbington, Kingswinford, Smestow, Upper Gornal, Wall Heath, Claverley and areas near to Wombourne, Staffordshire. Have fun with the search for a decent metal polishing contractor.

|

Ellesmere Port Metal Polishers |

TOP - Specialist Odd Job Man - Good Garden Clearance - Door Hanging Quotes - Kitchen Worktops Hastings - Door Installation Balderton - Odd Job Man Burnham on Crouch