Metal Polishers Whitstable UK

Metal Polishers Whitstable: Your quest for neighbourhood metal polishers should really begin below as you can very easily make use of our useful google map to get a displayed metal polisher within the Whitstable, Kent locality. See lots more metal polishers by clicking on the zoom out button.

Whitstable Metal Polishers: When you're using the net for your search, just simply opting for the top metal polisher rankings in a search engine would not quite often be the best method since these often probably won't turn out to be local trades-men. Your goal is to get metal polishers near to Whitstable, Kent.

Locating a really good metal polisher in your neighbourhood may not be as simple as it may sound, although without doubt searching the internet is the most common strategy these days.

Picking out a tradesman by using the initial listings in an internet search engine on the web, wouldn't in many cases be the right strategy, because they are quite often not in fact nearby metal polishers, but usually country wide metal polishing businesses.

The great thing is, you can find trustworthy polishing enterprises nearby that will do a superb job with no problems.

Individual referrals are needless to say the most suitable way to find a professional metal polisher, for that reason question anybody who you know who every so often makes use of metal polishers.

To uncover highly recommended professionals in some trades you might use the primary tradespeople referral internet sites for instance Trustatrader, My Builder, CheckaTrade or Rated People, when earlier clientele supply ratings and feedback.

To get providers, tradesmen and businesses not shown on this category of websites, you could actually experiment with one or a number of of these:

Free Index, 1st Directory, Wahanda, Business Magnet, Wampit, Opendi, My Local Services, Approved Business, Scoot, City Visitor, City Listings, Zettai, B2Index, Business Directory UK, UK Local Search, 192, Hotfrog, Yelp, My Sheriff, Gomy, Local Life, Local Data Search, Near, 4ni, Yell, 118 118, or other local business directories.

Locating a really good metal polisher in your neighbourhood may not be as simple as it may sound, although without doubt searching the internet is the most common strategy these days.

Picking out a tradesman by using the initial listings in an internet search engine on the web, wouldn't in many cases be the right strategy, because they are quite often not in fact nearby metal polishers, but usually country wide metal polishing businesses.

The great thing is, you can find trustworthy polishing enterprises nearby that will do a superb job with no problems.

Individual referrals are needless to say the most suitable way to find a professional metal polisher, for that reason question anybody who you know who every so often makes use of metal polishers.

To uncover highly recommended professionals in some trades you might use the primary tradespeople referral internet sites for instance Trustatrader, My Builder, CheckaTrade or Rated People, when earlier clientele supply ratings and feedback.

To get providers, tradesmen and businesses not shown on this category of websites, you could actually experiment with one or a number of of these:

Free Index, 1st Directory, Wahanda, Business Magnet, Wampit, Opendi, My Local Services, Approved Business, Scoot, City Visitor, City Listings, Zettai, B2Index, Business Directory UK, UK Local Search, 192, Hotfrog, Yelp, My Sheriff, Gomy, Local Life, Local Data Search, Near, 4ni, Yell, 118 118, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Whitstable include: polishing copper, reflective finishes, industrial and commercial polishing, same day polishing, polishing brass, polishing stainless steel, automotive polishing, metal fabrication, metal polishing aluminium, mirror polishes, commercial polishing, polishing nickel alloys, polishing metals, polishing engine parts, titanium polishing, metal finishing, circle finishes, metal polishing and finishing, commercial and super bright polishing, aluminium metal polishing, dull and satin polishing, decorative polishing, metal polishing motorcycle parts, polishing alloy wheels, on site polishing services, motorcycle metal polishing, custom metal polishing, industrial polishing, brushed finishes, vintage polishing, marine polishing.

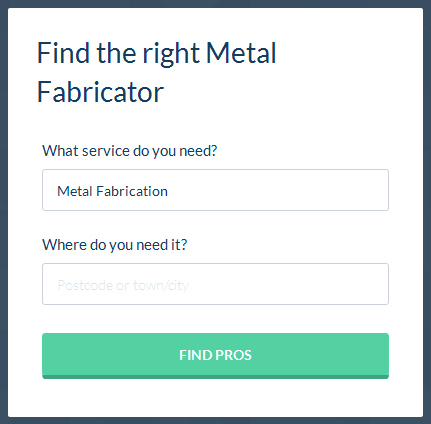

Find Whitstable Metalworkers Using Bark

| Locate a Metalworker in Whitstable |  |

Do-it-Yourself Metal Polishing Tips

The Principles of Metal Polishing - In most cases, metal finishing is required for aesthetics or clean-room uses. It really is among the most popular processes because of its use in intensifying the overall beauty of the product, for example, motorcycle parts, cookware or car parts. Similarly, lots of clean-rooms must have a shiny finish so to limit the permeability of the components which can cause debris to collect and contaminate. A really good illustration of this application might be in a vacuum chamber. You will discover several strategies to finish metals, and let's take a look at several of the processes required. Metals can be finished using chemicals, electromechanically, with purpose built buffing machines, or even by hand. A polishing compound or paste may be applied, which may include chromium oxide, tripoli, aluminum oxide, dolomite, chalk, limestone, or iron oxide. Polishing stainless steel, due to its low thermal conductivity, reasonably high viscidity, and hardness is considered the most time-consuming. In contrast, things made from non-ferrous metals are often more responsive to finishing, since these call for the lower amount of processes. When a superior processing quality is not important, increased pad speeds could be used. A decreased pad speed must be used when a good quality mirror finish is mandatory. Polishing buffs smeared in compound will be somewhat impacted by specific pressures on the pad. The power of the surface pressure may be accelerated within certain guidelines, though further overreaching the ideal amount of pressure not merely cuts down on the quality of the process, but additionally lessens the level of effectiveness, may well cause wear on the part, and there's moreover a tangible heating of the work-pieces, resulting from friction. When you are using thin items, it is higher heat (and a corresponding flexibility of the metal) that will sometimes cause materials to buckle, twist or flex. For the most part, it will require a trained technician to consider all these fundamentals to both avert harm to the metal part and to get the job done proficiently. To be able to substantially improve the standard of the resultant surface area, the finishing process ought to be executed with significantly less aggression and not a large amount of pressure so that you can subsequently produce a surface area with no scores or fine lines coming from the polishing procedure, subsequently arriving at a brilliant mirror finish.

When a superior processing quality is not important, increased pad speeds could be used. A decreased pad speed must be used when a good quality mirror finish is mandatory. Polishing buffs smeared in compound will be somewhat impacted by specific pressures on the pad. The power of the surface pressure may be accelerated within certain guidelines, though further overreaching the ideal amount of pressure not merely cuts down on the quality of the process, but additionally lessens the level of effectiveness, may well cause wear on the part, and there's moreover a tangible heating of the work-pieces, resulting from friction. When you are using thin items, it is higher heat (and a corresponding flexibility of the metal) that will sometimes cause materials to buckle, twist or flex. For the most part, it will require a trained technician to consider all these fundamentals to both avert harm to the metal part and to get the job done proficiently. To be able to substantially improve the standard of the resultant surface area, the finishing process ought to be executed with significantly less aggression and not a large amount of pressure so that you can subsequently produce a surface area with no scores or fine lines coming from the polishing procedure, subsequently arriving at a brilliant mirror finish. Also find metal polishers in: Yorkletts, Hernhill, Fordwich , Herne Bay, Westbere, Tankerton, Seasalter, Herne Common, Faversham, Rough Common, Tyler Hill, Chestfield, Graveney, Dargate, Blean, Sturry, Hernhill, Broadoak and areas near to Whitstable, Kent. Maybe our helpful tips helped you to find a decent metal polishers firm.

TOP - Affordable Odd Job Man - Rated Garden Clearance - Door Hanging Quotations - Garden Clearance Glenfield - Door Installation Nailsea - Odd Job Man North Walsham