Metal Polishers Whitby UK

Metal Polishers Whitby: Should you be looking for a nearby metal polisher, you may conveniently make use of the Google map below to determine currently displayed metal polishers contained in the Whitby, Yorkshire locality. When none display, retrieve closest metal polishers merely by clicking the pan out button.

Whitby Metal Polishers: Asking near your neighbourhood, is an ideal strategy for finding a reliable metal polishing firm, recommendations and testimonials by clients who've utilised them formerly should really give reliable people. We after all are hoping to find metal polishers near Whitby, Yorkshire.

Choosing a really good metal polisher in your neighbourhood may not be so simple as it sounds, but unquestionably browsing the web is considered the most successful approach at present.

If you use the internet for the search, simply opting for the first metal polisher results in the search engines will not quite often be the best strategy because these quite often won't in fact be local trades-people.

Reliable metal polishing companies however, may not be that difficult to identify, you will effortlessly be able to find one around.

Personal testimonials are obviously the most suitable option to find a good metal polisher, therefore question anybody who you know who routinely makes use of these services.

You may even acquire cost-free estimates and read past homeowners critiques and recommendations on the various trades-people's assessment sites in particular Rated People, CheckaTrade, Trustatrader, Bark or My Builder.

Regarding specialities, skillsets and services not showing on these sorts of online websites, you may look at one or a few of these:

The Sun Business Directory, Tipped, Yelp, Britaine, 118 118, Opendi, 2 Find Local, City Listings, Zettai, 192, BizzBuzz, U Find Us, Thomson Local, UK Directory, Touch Local, Fyple, Near, UK Internet Directory, Local Life, Free Index, Local Data Search, Top Pages, Approved Business, Places Locally, Business Directory UK, Gomy, or other local business directories.

Choosing a really good metal polisher in your neighbourhood may not be so simple as it sounds, but unquestionably browsing the web is considered the most successful approach at present.

If you use the internet for the search, simply opting for the first metal polisher results in the search engines will not quite often be the best strategy because these quite often won't in fact be local trades-people.

Reliable metal polishing companies however, may not be that difficult to identify, you will effortlessly be able to find one around.

Personal testimonials are obviously the most suitable option to find a good metal polisher, therefore question anybody who you know who routinely makes use of these services.

You may even acquire cost-free estimates and read past homeowners critiques and recommendations on the various trades-people's assessment sites in particular Rated People, CheckaTrade, Trustatrader, Bark or My Builder.

Regarding specialities, skillsets and services not showing on these sorts of online websites, you may look at one or a few of these:

The Sun Business Directory, Tipped, Yelp, Britaine, 118 118, Opendi, 2 Find Local, City Listings, Zettai, 192, BizzBuzz, U Find Us, Thomson Local, UK Directory, Touch Local, Fyple, Near, UK Internet Directory, Local Life, Free Index, Local Data Search, Top Pages, Approved Business, Places Locally, Business Directory UK, Gomy, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Whitby include: aluminium polishing, vintage polishing, polishing iron, sheet metal polishing, marine polishing, polishing internal bores, bespoke polishing, metal fabrication, trusted metal polishers, polishing alloy wheels, polishing machine parts, commercial and super bright polishing, mirror polishes, dull and satin polishing, polishing engine parts, polishing brass, brushed finishes, polishing copper, metal polishing and buffing, grained finishes, metal polishing aluminium, metal finishing, industrial polishing, circle finishes, specialist angle polishing, motorcycle metal polishing, same day polishing, industrial and commercial polishing, duplex finishes, metal polishing and finishing, custom metal polishing.

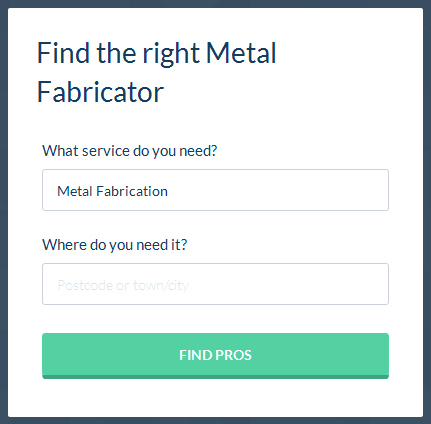

Find Whitby Metalworkers Using Bark

| Identify a Metalworker in Whitby |  |

Do-it-Yourself Metal Polishing Tips

An Overview of Metal Polishing - Most often, metal polishing is essential for aesthetic reasons or clean-room applications. It really is one of the most prominent practices because of its use in intensifying the overall attractiveness of the item, such as, motorbike parts, car parts or kitchenware. Similarly, numerous clean-rooms will require a shiny finish to lessen the permeability of the metal surfaces which will cause particles to gather and contaminate. A superb instance of this application could be in vacuum chambers. You will discover a great number of ways to polish metal, and we will look at a few of the techniques required. Metal may be finished chemically, electromechanically, using special buffing machines, and also manually. A polishing compound or paste can be applied, that could include limestone, aluminum oxide, dolomite, chalk, chromium oxide, tripoli, or iron oxide. Polishing stainless steel, because of its lousy thermal conductivity, its hardness, and its quite high viscidity is amongst the time-consuming. On the contrary, products manufactured from non-ferrous metals tend to be more responsive to finishing, because these demand the least amount of treatments. Any time a greater processing quality is simply not crucial, swifter pad speeds can be utilised. A reduced pad speed is used if a superior quality mirror finish is obligatory. Polishing buffs daubed with paste are substantially affected by specific loads on the buffing pad. The intensity of the surface pressure can be accelerated to a specified extent, though overreaching the optimum level of pressure not simply minimizes the quality level of the process, but additionally degrades efficiency, can bring about wear on the product, and there is also an evident overheating of the work-pieces, brought about by friction. When working thinner material, it will be greater heat (and the relating flexibility of the metal) that can cause materials to distort, bend or twist. Generally speaking, it will take a professional polisher to think about each one of these variables to both not cause harm to the metal part and to perform the task proficiently. For you to radically increase the standard of the resulting surface, the finishing procedure must be completed with less power and not a large amount of pressure to be able to consequently deliver a surface that is free of scratches or marks coming from the buffing process, subsequently arriving at a lovely mirror finish.

Any time a greater processing quality is simply not crucial, swifter pad speeds can be utilised. A reduced pad speed is used if a superior quality mirror finish is obligatory. Polishing buffs daubed with paste are substantially affected by specific loads on the buffing pad. The intensity of the surface pressure can be accelerated to a specified extent, though overreaching the optimum level of pressure not simply minimizes the quality level of the process, but additionally degrades efficiency, can bring about wear on the product, and there is also an evident overheating of the work-pieces, brought about by friction. When working thinner material, it will be greater heat (and the relating flexibility of the metal) that can cause materials to distort, bend or twist. Generally speaking, it will take a professional polisher to think about each one of these variables to both not cause harm to the metal part and to perform the task proficiently. For you to radically increase the standard of the resulting surface, the finishing procedure must be completed with less power and not a large amount of pressure to be able to consequently deliver a surface that is free of scratches or marks coming from the buffing process, subsequently arriving at a lovely mirror finish. Also find metal polishers in: Ruswarp, Saltwick Bay, Sneaton, Stainsacre, Sleights, High Stakesby, Briggswath, East Row, Robin Hoods Bay, High Hawkser, Iburndale, Newholme , Dunsley, Ugglebarnby, Aislaby, Raithwaite and areas near to Whitby, Yorkshire. We trust we aided with your search for a decent metal polishing company.

|

Sutton-in-Ashfield Metal Polishers |

TOP - Odd Job Man - Economical Garden Clearance - Door Hanging - Garden Clearance Totton and Eling - Door Installation Amersham - Odd Job Man Madeley