Metal Polishers Waddington UK

Metal Polishers Waddington: Anytime you would like to seek out assistance from a nearby metal polisher, you should employ this web page to uncover currently itemized local area metal polishers for the Waddington, Lincolnshire local area. Left click the pan out whenever no metal polishers appear on our map.

Waddington Metal Polishers: You can furthermore receive cost-free estimates and read previous homeowners comments and testimonials on one of the many many tradesmen recommendation websites for example Rated People, Bark, CheckaTrade, Trustatrader or My Builder. The intention is to get metal polishers in close proximity to Waddington, Lincolnshire.

Picking a dependable metal polisher near to your home may not be as easy as it sounds, though without doubt checking out the internet is regarded as the successful strategy at the moment.

You'll want to get a local metal polisher, and so merely selecting the initial results in google search on your pc, isn't be the best method, those top results are often for nationwide companies.

Luckily, there are lots of reliable polishing businesses in your area who will do a good quality job without any hassles.

When a neighbor or local office building has their own windows often cleaned, it is easy to see if they will recommend their particular favored metal polisher.

To find endorsed experts in certain skills feel free to use the foremost trades-people's testimonial web sites in particular CheckaTrade, My Builder, Rated People or Trustatrader, whereby former clients give reports and critiques.

Regarding services, trades and specialities not shown on these types of online websites, you can simply experiment with one or two of these:

2 Find Local, Business Magnet, BizzBuzz, Places Locally, UK Local Search, Top Pages, Business Directory UK, 1st Directory, The Sun Business Directory, 118 118, Yell, Tipped, City Listings, Touch Local, 192, Wahanda, Opendi, Gomy, City Local, Thomson Local, Zettai, My Local Services, 4ni, Wampit, Hotfrog, UK Directory, or other local business directories.

Picking a dependable metal polisher near to your home may not be as easy as it sounds, though without doubt checking out the internet is regarded as the successful strategy at the moment.

You'll want to get a local metal polisher, and so merely selecting the initial results in google search on your pc, isn't be the best method, those top results are often for nationwide companies.

Luckily, there are lots of reliable polishing businesses in your area who will do a good quality job without any hassles.

When a neighbor or local office building has their own windows often cleaned, it is easy to see if they will recommend their particular favored metal polisher.

To find endorsed experts in certain skills feel free to use the foremost trades-people's testimonial web sites in particular CheckaTrade, My Builder, Rated People or Trustatrader, whereby former clients give reports and critiques.

Regarding services, trades and specialities not shown on these types of online websites, you can simply experiment with one or two of these:

2 Find Local, Business Magnet, BizzBuzz, Places Locally, UK Local Search, Top Pages, Business Directory UK, 1st Directory, The Sun Business Directory, 118 118, Yell, Tipped, City Listings, Touch Local, 192, Wahanda, Opendi, Gomy, City Local, Thomson Local, Zettai, My Local Services, 4ni, Wampit, Hotfrog, UK Directory, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Waddington include: duplex finishes, sheet metal polishing, aluminium polishing, quality metal polishing, automotive polishing, polishing iron, polishing copper, custom metal polishing, specialist angle polishing, trusted metal polishers, mirror polishes, reflective finishes, polishing internal bores, metal polishing services, bespoke polishing, on site polishing services, polishing brass, industrial and commercial polishing, polishing metals, same day polishing, vintage polishing, polishing nickel alloys, grained finishes, metal polishing aluminium, industrial polishing, metal polishing motorcycle parts, brushed finishes, marine polishing, motorcycle metal polishing, special finishes, polishing alloy wheels.

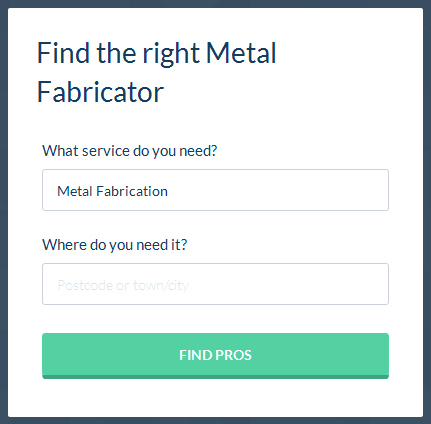

Find Waddington Metalworkers on Bark

| Identify a Metalworker in Waddington |  |

Do-it-Yourself Metal Polishing Tips

Novices Guide to Metal Polishing - Typically, the finishing of metal is important for a pleasing appearance and for clean-room applications. It really is one of the more favored practices simply because of its utility in improving upon the original attractiveness of the items, for example, motorbike parts, automobile parts or kitchenware. Similarly, a great many clean-rooms want a shiny finish in an effort to limit the porosity of the material which often can result in particles to build up and contaminate. A really good instance of this practice might be in a vacuum chamber. You'll discover lots of different ways to polish metals, and here we are going to take a look at a little pertaining to several of the processes required. Metal can be finished manually, using purpose built buffing machines, electromechanically or chemically. A finishing compound or paste is usually utilised, which might consist of tripoli, dolomite, limestone, chalk, aluminum oxide, chromium oxide, or iron oxide. Buffing stainless steel, because of its poor thermal conductivity, quite high viscosity, and hardness is just about the time intensive. In contrast, goods built from non-ferrous metals are more receptive to polishing, simply because these require the lower number of operations. Where a superior processing quality isn't really required, quicker pad speeds can be used. A lower pad speed is commonly used any time a good quality mirror finish is expected. Polishing buffs smothered in paste will be markedly affected by the pressures on the finishing pad. The concentration of the pressure on the surface may be heightened within certain boundaries, though going beyond the optimum level of pressure not only decreases the quality of the procedure, but in addition degrades performance, can result in wear to the part, and there is also an obvious overheating of the work-pieces, as a result of friction. When you are working on thin material, it will be elevated heat (and a ensuing bendability of the metal) that cause items to distort, twist or buckle. Generally, it needs a specialized technician to look at every one of these variables to both avert harm to the piece and to deliver the results effectively. To be able to substantially improve the standard of the completed surface area, the finishing action should be completed with a reduced amount of power and not so much pressure so as to in the end complete a surface area that doesn't have any scratches or fine lines brought about by the finishing procedure, thereby ending up with a brilliant mirror finish.

Where a superior processing quality isn't really required, quicker pad speeds can be used. A lower pad speed is commonly used any time a good quality mirror finish is expected. Polishing buffs smothered in paste will be markedly affected by the pressures on the finishing pad. The concentration of the pressure on the surface may be heightened within certain boundaries, though going beyond the optimum level of pressure not only decreases the quality of the procedure, but in addition degrades performance, can result in wear to the part, and there is also an obvious overheating of the work-pieces, as a result of friction. When you are working on thin material, it will be elevated heat (and a ensuing bendability of the metal) that cause items to distort, twist or buckle. Generally, it needs a specialized technician to look at every one of these variables to both avert harm to the piece and to deliver the results effectively. To be able to substantially improve the standard of the completed surface area, the finishing action should be completed with a reduced amount of power and not so much pressure so as to in the end complete a surface area that doesn't have any scratches or fine lines brought about by the finishing procedure, thereby ending up with a brilliant mirror finish. Also find metal polishers in: Bracebridge Heath, Navenby, Bracebridge Low Fields, Lincoln, Potterhanworth, Scopwick, Branston, Bassingham, Aubourn, Nocton, Coleby, South Hykeham , North Hykeham, Harmston and areas near to Waddington, Lincolnshire. Most likely our techniques helped you to find a first-rate local metal polishing service.

|

Sutton-in-Ashfield Metal Polishers |

TOP - Trustworthy Odd Job Man - Cheap Garden Clearance - Door Fitters Experts - Kitchen Worktops Surbiton - Door Installation Chalfont St Peter - Odd Job Man Leek