Metal Polishers Ryde UK

Metal Polishers Ryde: The search for local metal polishers should begin on this site as you could easily utilize the simple google map to find a listed metal polisher in the Ryde, Isle of Wight area. Whenever none can be seen, retrieve most near at hand metal polishers simply by clicking on the zoom out button.

Ryde Metal Polishers: Searching for a reliable metal polisher in your neighbourhood is not necessarily as simple as it appears, but without doubt scouting around the world wide web is the most widespread approach these days. Our focus is to find metal polishers near to Ryde, Isle of Wight.

There are different strategies you can employ to locate a suitable metal polisher, with the yellow pages, local classified ads plus the net, among the most fashionable.

It is crucial to track down a localized metal polishing business, so simply just picking out the highest results in a search engine on your pc, wouldn't be the best policy, the topmost rankings are in many cases for nationwide companies.

Trusted polishing enterprises though, aren't going to be that tough to identify, you will quickly be able to find one nearby.

Asking round your neighbourhood, is the right option to find a skilled metal polishing business, testimonials by clients who used them in the past should certainly give you an idea of effective businesses.

It's possible to additionally get cost-free quotes and browse earlier homeowners testimonials and comments on a numerous tradespeople review web sites including My Builder, CheckaTrade, Bark, Trustatrader or Rated People.

When thinking of skills, occupations and providers that are not displayed on these types of online sites, you will be able to experiment with one or a few of these:

Yell, City Listings, Thomson Local, City Visitor, Wahanda, Places Locally, Approved Business, B2Index, The Sun Business Directory, Business Directory UK, Local Data Search, Business Magnet, City Local, BizzBuzz, My Local Services, Local Life, Britaine, Top Pages, Brown Book, Opendi, Tipped, Fyple, Wampit, Zettai, Near, 2 Find Local, or other local business directories.

There are different strategies you can employ to locate a suitable metal polisher, with the yellow pages, local classified ads plus the net, among the most fashionable.

It is crucial to track down a localized metal polishing business, so simply just picking out the highest results in a search engine on your pc, wouldn't be the best policy, the topmost rankings are in many cases for nationwide companies.

Trusted polishing enterprises though, aren't going to be that tough to identify, you will quickly be able to find one nearby.

Asking round your neighbourhood, is the right option to find a skilled metal polishing business, testimonials by clients who used them in the past should certainly give you an idea of effective businesses.

It's possible to additionally get cost-free quotes and browse earlier homeowners testimonials and comments on a numerous tradespeople review web sites including My Builder, CheckaTrade, Bark, Trustatrader or Rated People.

When thinking of skills, occupations and providers that are not displayed on these types of online sites, you will be able to experiment with one or a few of these:

Yell, City Listings, Thomson Local, City Visitor, Wahanda, Places Locally, Approved Business, B2Index, The Sun Business Directory, Business Directory UK, Local Data Search, Business Magnet, City Local, BizzBuzz, My Local Services, Local Life, Britaine, Top Pages, Brown Book, Opendi, Tipped, Fyple, Wampit, Zettai, Near, 2 Find Local, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Ryde include: mirror polishes, polishing brass, sheet metal polishing, quality metal polishing, polishing stainless steel, custom metal polishing, polishing engine parts, specialist angle polishing, duplex finishes, bespoke polishing, metal fabrication, same day polishing, trusted metal polishers, polishing metals, polishing bronze, polishing nickel alloys, special finishes, commercial polishing, vintage polishing, metal polishing and buffing, decorative polishing, metal finishing, brushed finishes, polishing internal bores, polishing alloy wheels, grained finishes, industrial polishing, metal polishing and finishing, titanium polishing, metal polishing aluminium, metal polishing services.

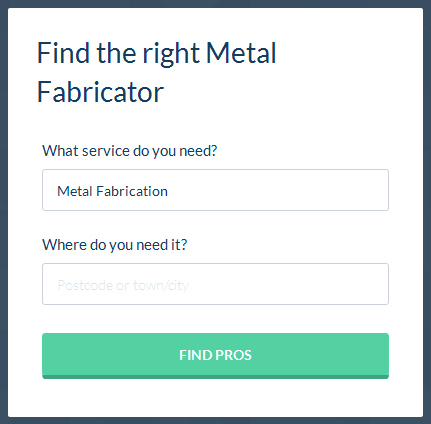

Find Ryde Metalworkers Using Bark

| Get a Metalworker in Ryde |  |

Do-it-Yourself Metal Polishing Tips

Basic Metal Finishing - Nearly always, metal polishing is desirable for appearance or clean-room applications. It is among the most widely used solutions because of its usefulness in bettering the natural beauty of the product, for instance, motor bike parts, cookware or automobile parts. Also, a great many clean-rooms will want a burnished finish in order to lower the perviousness of the metal surfaces that can result in debris to collect and contaminate. A good example of this practice might be in vacuum chambers. You'll find a great number of ways to polish metals, and let's have a peek at a few of the procedures involved. Metals may be polished manually, using purpose made buffing machines, electromechanically or chemically. A special finishing paste or compound can be employed, which will incorporate aluminum oxide, tripoli, limestone, chalk, chromium oxide, dolomite, or iron oxide. Finishing stainless steel, due to its poor thermal conductivity, its hardness, and its relatively high viscosity is normally one of the most time intensive. However, merchandise produced with non-ferrous metals are more amenable to finishing, simply because these require the minimum amount of treatments. Any time a greater processing quality will not be called for, quicker pad speeds can be utilized. A slower pad speed can be used if a high standard mirror finish is expected. Finishing buffs plastered with paste can be greatly affected by the load on the pad. The concentration of the surface pressure may be elevated within certain confines, though further exceeding the correct amount of load not simply reduces the quality of treatment, but additionally degrades performance, can lead to wear to the product, and in addition an evident heating of the work-pieces, thanks to friction. When polishing thin objects, it's raised heat (and the relating flexibility of the material) that causes elements to flex, bend or twist. Generally, it will take a trained polisher to look at each one of these points to equally not cause harm to the part and to give good results efficiently. To help substantially enhance the standard of the resultant surface, the polishing action will have to be accomplished with a lesser amount of aggression and not so much force to be able to finally complete a surface that doesn't have any scratches or fine lines resulting from the buffing process, therefore ending up with a beautiful mirror finish.

Any time a greater processing quality will not be called for, quicker pad speeds can be utilized. A slower pad speed can be used if a high standard mirror finish is expected. Finishing buffs plastered with paste can be greatly affected by the load on the pad. The concentration of the surface pressure may be elevated within certain confines, though further exceeding the correct amount of load not simply reduces the quality of treatment, but additionally degrades performance, can lead to wear to the product, and in addition an evident heating of the work-pieces, thanks to friction. When polishing thin objects, it's raised heat (and the relating flexibility of the material) that causes elements to flex, bend or twist. Generally, it will take a trained polisher to look at each one of these points to equally not cause harm to the part and to give good results efficiently. To help substantially enhance the standard of the resultant surface, the polishing action will have to be accomplished with a lesser amount of aggression and not so much force to be able to finally complete a surface that doesn't have any scratches or fine lines resulting from the buffing process, therefore ending up with a beautiful mirror finish. Also find metal polishers in: Binstead, Oakfield, Bembridge, Spring Vale, Quarr Hill, St Helens, Upton, Elmfield, Nettlestone, Wootton Bridge, Arreton, Seaview, Swanmore, Havenstreet, Haylands, Newchurch , Brading and areas near to Ryde, Isle of Wight. Enjoy searching for a reliable metal polishing expert.

TOP - Affordable Odd Job Man - Approved Garden Clearance - Door Hanging - Kitchen Worktops Lowton - Door Installation Northfield - Odd Job Man Deeping St James