Metal Polishers Norfolk UK

Metal Polishers Norfolk: In case you are on the lookout for a nearby metal polisher, you'll be able to ideally try the interactive map on this page to spot actively displayed metal polishers within the Norfolk, England local area. Find far more metal polishers by left-clicking the minus button (zoom out) navigation button.

Norfolk Metal Polishers: Reliable companies though, don't seem to be that tough to find, you will easily manage to locate one close by. Your focus is to identify metal polishers near to Norfolk, England.

There are lots of strategies you can use in finding a good metal polisher, with the world wide web, the yellow pages plus the local classified ads, being the best.

Choosing a tradesman by using the highest results in a search engine on the web, may well not turn out to be the best approach, since these are sometimes not in fact nearby metal polishers, but oftentimes nationwide companies.

Efficient businesses though, are generally not that difficult to identify, you will easily manage to identify one in your area.

Any time a neighbour or even close by office building has their windows often maintained and cleaned, it is easy to see if they will endorse their preferred metal polishing business.

You could additionally access clients ratings and recommendations on one of the few primary tradespeople assessment sites including CheckaTrade, Trustatrader, My Builder or Rated People, where you'll be able to even obtain a number of free estimates.

With regards to specialists, trades and specialities that are not shown on this category of online websites, you could actually try one or a couple of of these:

My Local Services, Yelp, UK Directory, Local Data Search, My Sheriff, Wahanda, Places Locally, B2Index, Business Magnet, Tipped, 192, Near, Fyple, Hotfrog, U Find Us, Touch Local, 4ni, Britaine, Yalwa, Yell, Brown Book, 118 118, City Local, Scoot, Local Life, 1st Directory, or other local business directories.

There are lots of strategies you can use in finding a good metal polisher, with the world wide web, the yellow pages plus the local classified ads, being the best.

Choosing a tradesman by using the highest results in a search engine on the web, may well not turn out to be the best approach, since these are sometimes not in fact nearby metal polishers, but oftentimes nationwide companies.

Efficient businesses though, are generally not that difficult to identify, you will easily manage to identify one in your area.

Any time a neighbour or even close by office building has their windows often maintained and cleaned, it is easy to see if they will endorse their preferred metal polishing business.

You could additionally access clients ratings and recommendations on one of the few primary tradespeople assessment sites including CheckaTrade, Trustatrader, My Builder or Rated People, where you'll be able to even obtain a number of free estimates.

With regards to specialists, trades and specialities that are not shown on this category of online websites, you could actually try one or a couple of of these:

My Local Services, Yelp, UK Directory, Local Data Search, My Sheriff, Wahanda, Places Locally, B2Index, Business Magnet, Tipped, 192, Near, Fyple, Hotfrog, U Find Us, Touch Local, 4ni, Britaine, Yalwa, Yell, Brown Book, 118 118, City Local, Scoot, Local Life, 1st Directory, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Norfolk include: polishing bronze, polishing stainless steel, polishing machine parts, brushed finishes, aluminium metal polishing, metal polishing and buffing, polishing nickel alloys, quality metal polishing, metal polishing services, industrial polishing, titanium polishing, metal polishing aluminium, linear metal polishing, aluminium polishing, trusted metal polishers, reflective finishes, decorative polishing, metal polishing and finishing, bespoke polishing, metal finishing, polishing copper, polishing alloy wheels, on site polishing services, polishing engine parts, polishing iron, custom metal polishing, same day polishing, sheet metal polishing, commercial polishing, circle finishes, metal fabrication.

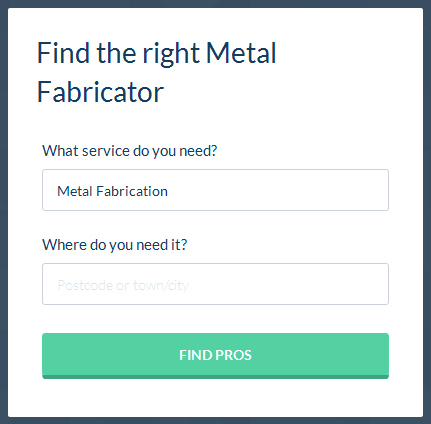

Find Norfolk Metalworkers at Bark

| Pinpoint a Metalworker in Norfolk |  |

Do-it-Yourself Metal Polishing Tips

An Outline of Metal Finishing - Frequently, the finishing of metal is required for a pleasing appearance or for clean-room applications. It's among the most preferred procedures because of its effectiveness in escalating the overall attractiveness of the item, as an example, motorcycle parts, car parts or kitchenware. Aside from that, plenty of clean-rooms will want a lustrous finish so as to lessen the penetrability of the components that may cause dirt to build up and contaminate. A really good illustration of this implementation might be in vacuum chambers. There are certainly a lot of ways to polish metals, and we can think about a few of the procedures involved. Metal may be burnished electromechanically, by means of chemicals, by hand, or with purpose made buffing machines. A particular buffing compound or paste is routinely used, that might consist of chromium oxide, tripoli, aluminum oxide, dolomite, chalk, limestone, or iron oxide. Buffing stainless steel, due to its mediocre thermal conductivity, quite high viscidity, and hardness is just about the time-consuming. In contrast, goods produced with non-ferrous metals tend to be more responsive to buffing, because these call for the lowest number of treatments. Any time a high processing quality will not be mandatory, increased pad speeds may be used. A decreased pad speed is commonly used any time a good quality mirror finish is desired. Polishing buffs smeared with paste will be markedly impacted by specific pressures on the surface of the pad. The concentration of the pressure on the surface might be increased to a definite scope, although implementing over the optimal amount of pressure not simply decreases the quality level of the process, but additionally worsens effectiveness, causes wear on the part, and there's also a conspicuous heating of the material being worked on, due to friction. When polishing thinner pieces, it's higher heat (and the relating bendability of the material) that will possibly cause components to flex, warp or buckle. In general, it will take a highly trained technician to take into account each one of these things to equally avoid damage to the workpiece and to perform the project adequately. To help you radically enhance the standard of the completed finish, the finishing process needs to be carried out with much less aggression and not a large amount of pressure to be able to ultimately complete a surface with no scratches or fine lines as a consequence of the polishing process, thus ending up with a lovely mirror finish.

Any time a high processing quality will not be mandatory, increased pad speeds may be used. A decreased pad speed is commonly used any time a good quality mirror finish is desired. Polishing buffs smeared with paste will be markedly impacted by specific pressures on the surface of the pad. The concentration of the pressure on the surface might be increased to a definite scope, although implementing over the optimal amount of pressure not simply decreases the quality level of the process, but additionally worsens effectiveness, causes wear on the part, and there's also a conspicuous heating of the material being worked on, due to friction. When polishing thinner pieces, it's higher heat (and the relating bendability of the material) that will possibly cause components to flex, warp or buckle. In general, it will take a highly trained technician to take into account each one of these things to equally avoid damage to the workpiece and to perform the project adequately. To help you radically enhance the standard of the completed finish, the finishing process needs to be carried out with much less aggression and not a large amount of pressure to be able to ultimately complete a surface with no scratches or fine lines as a consequence of the polishing process, thus ending up with a lovely mirror finish. Also find metal polishers in: Dersingham, Aylsham, Docking, Hingham, Acle, Cromer, Hunstanton, Loddon, Stalham, Attleborough, Norwich, Wymondham, Reepham, Diss , Gorleston, North Walsham, Kings Lynn and areas near to Norfolk, England. Good luck with browsing for a reputable metal polishing company.

TOP - Odd Job Man - Reliable Garden Clearance - Door Fitters Professionals - Kitchen Worktops Kempston - Door Installation Handforth - Odd Job Man Wath Upon Dearne