Metal Polishers Meopham UK

Metal Polishers Meopham: When you would like to find the expertise of any nearby metal polisher, you should employ this webpage to locate currently itemized nearby metal polishers within the Meopham, Kent district. If ever there isn't any results displaying on the map, hit the pan out button.

Meopham Metal Polishers: Nevertheless, there are efficient polishing businesses close by who will do a pretty good job without any headaches. We obviously require metal polishers in the region of Meopham, Kent.

Are your windows appearing somewhat grimy? Then you will certainly be seeking a suitable metal polisher whom you can count on to do the task.

If you use the internet for the search, simply picking out the first metal polisher listings on an online search engine usually will not always be the correct approach since these in many cases will most likely not turn out to be local people.

Undoubtedly there are loads of dependable polishing enterprises around who deliver a good service without giving you any worries.

When a neighbour or close by workplace has their own windows constantly cleaned, you might encourage them to recommend their favourite metal polisher.

To look for recommended specialists in many trades you need to use a main trades-people's review sites like My Builder, Trustatrader, Rated People or CheckaTrade, when earlier clients share critiques and testimonials.

With regards to businesses, trades and companies that are not listed on these kinds of online websites, you could possibly consider one or some of these:

UK Local Search, 4ni, The Sun Business Directory, UK Internet Directory, Brown Book, Gomy, Wampit, Zettai, Near, Yell, BizzBuzz, Local Data Search, U Find Us, UK Directory, City Local, Top Pages, City Listings, Business Directory UK, Opendi, Yelp, Fyple, 118 118, Scoot, 192, Britaine, Local Life, or other local business directories.

Are your windows appearing somewhat grimy? Then you will certainly be seeking a suitable metal polisher whom you can count on to do the task.

If you use the internet for the search, simply picking out the first metal polisher listings on an online search engine usually will not always be the correct approach since these in many cases will most likely not turn out to be local people.

Undoubtedly there are loads of dependable polishing enterprises around who deliver a good service without giving you any worries.

When a neighbour or close by workplace has their own windows constantly cleaned, you might encourage them to recommend their favourite metal polisher.

To look for recommended specialists in many trades you need to use a main trades-people's review sites like My Builder, Trustatrader, Rated People or CheckaTrade, when earlier clients share critiques and testimonials.

With regards to businesses, trades and companies that are not listed on these kinds of online websites, you could possibly consider one or some of these:

UK Local Search, 4ni, The Sun Business Directory, UK Internet Directory, Brown Book, Gomy, Wampit, Zettai, Near, Yell, BizzBuzz, Local Data Search, U Find Us, UK Directory, City Local, Top Pages, City Listings, Business Directory UK, Opendi, Yelp, Fyple, 118 118, Scoot, 192, Britaine, Local Life, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Meopham include: metal polishing and finishing, sheet metal polishing, quality metal polishing, polishing brass, industrial polishing, polishing internal bores, metal polishing and buffing, dull and satin polishing, aluminium polishing, special finishes, polishing alloy wheels, bespoke polishing, linear metal polishing, grained finishes, industrial and commercial polishing, metal polishing motorcycle parts, decorative polishing, vintage polishing, polishing iron, circle finishes, polishing metals, same day polishing, metal finishing, polishing stainless steel, commercial and super bright polishing, polishing bronze, metal polishing aluminium, automotive polishing, polishing engine parts, brushed finishes, on site polishing services.

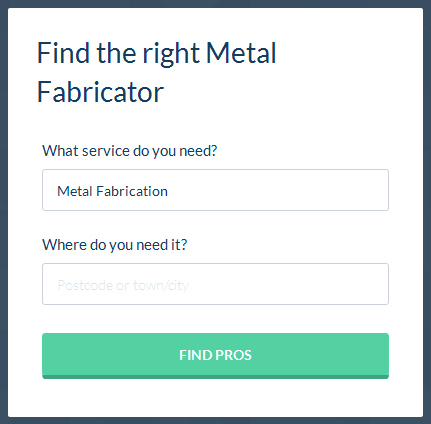

Find Meopham Metalworkers on Bark

| Locate a Metalworker in Meopham |  |

Do-it-Yourself Metal Polishing Tips

Beginners Guide to Metal Polishing - Nearly always, metal finishing is desirable for aesthetics and clean-room application. It really is among the most common solutions due to its success in enhancing the overall attractiveness of the item, for example, vehicle parts, cookware or motor bike parts. Aside from that, a great many clean-rooms will require a burnished finish so to limit the perviousness of the metal surfaces which could cause particles to collect and contaminate. A good illustration of this application might be in a vacuum chamber. There exist a large number of approaches to polish metals, and we can look into several of the methods involved. Various metals may be finished by hand, with purpose made buffing machines, electromechanically or using chemicals. A particular finishing paste or compound may be utilised, which might consist of dolomite, aluminum oxide, tripoli, chromium oxide, limestone, chalk, or iron oxide. Finishing stainless steel, because of its poor thermal conductivity, quite high viscosity, and hardness is among the most time intensive. More over, merchandise produced from non-ferrous metal are often more receptive to buffing, simply because these demand the lowest number of processes. Where a greater processing quality will not be demanded, faster pad speeds can be utilised. A lower pad speed is needed in the event that a high standard mirror finish is mandatory. Polishing buffs smothered with compound can be dramatically affected by the load on the surface of the pad. The level of the pressure on the surface can be increased to a certain extent, although further surpassing the ideal level of pressure not merely reduces the quality level of the procedure, but additionally worsens efficiency, might result in wear on the component, and there is moreover an evident heating of the metal being worked on, thanks to friction. With thin objects, it will be increased temperature (and the relating bendability of the material) that will in all probability cause items to flex, buckle or warp. In general, it needs a proficient technician to look at all these things to equally avert harm to the metal part and to deliver the results proficiently. To help you radically improve the quality of the final finish, the finishing action is required to be carried out with not as much vigour and not as much pressure to be able to in due course produce a surface area that is free of scratches or fine lines as a consequence of the polishing process, therefore arriving at a fabulous mirror finish.

Where a greater processing quality will not be demanded, faster pad speeds can be utilised. A lower pad speed is needed in the event that a high standard mirror finish is mandatory. Polishing buffs smothered with compound can be dramatically affected by the load on the surface of the pad. The level of the pressure on the surface can be increased to a certain extent, although further surpassing the ideal level of pressure not merely reduces the quality level of the procedure, but additionally worsens efficiency, might result in wear on the component, and there is moreover an evident heating of the metal being worked on, thanks to friction. With thin objects, it will be increased temperature (and the relating bendability of the material) that will in all probability cause items to flex, buckle or warp. In general, it needs a proficient technician to look at all these things to equally avert harm to the metal part and to deliver the results proficiently. To help you radically improve the quality of the final finish, the finishing action is required to be carried out with not as much vigour and not as much pressure to be able to in due course produce a surface area that is free of scratches or fine lines as a consequence of the polishing process, therefore arriving at a fabulous mirror finish. Also find metal polishers in: Higham, Luddesdown, Upper Halling, Horton Kirby, Vigo, Istead Rise, New Ash Green , Stanstead, Trottiscliffe, Shorne, Ash, Hartley, Cuxton, Longfield, West Kingsdown and areas near to Meopham, Kent. We hope we aided with the quest for a decent local metal polishing business.

|

Leamington Spa Metal Polishers |

TOP - Expert Odd Job Man - Reviewed Garden Clearance - Door Fitters Professionals - Kitchen Worktops Shenstone - Door Installation Stretford - Odd Job Man Weston Super Mare