Metal Polishers Hatfield UK

Metal Polishers Hatfield: In case you're struggling to find a local metal polisher, you can ideally try the map on this page to determine available itemized metal polishers contained in the Hatfield, Hertfordshire district. Any time none are displayed, get closest metal polishers simply by clicking the pan out button.

Hatfield Metal Polishers: Asking in your neighborhood, is an awesome strategy for finding an outstanding metal polishing business, referrals by individuals who have chosen them formerly should certainly provide effective tradesmen. We however are searching for metal polishers in the region of Hatfield, Hertfordshire.

Are the home's windows appearing a bit mucky? Then you will definitely be searching for a quality metal polisher who you can have confidence in to take care of the work.

Choosing a tradesman using the first search results in google search on the net, will not turn out to be the correct policy, as these are in many cases not really localized metal polishers, but generally country wide metal polishing businesses.

Needless to say there has to be quite a lot of responsible polishing businesses in your area who provide a good quality service without any dilemmas.

Inquiring close to your local area, is a good option to find a decent metal polisher, testimonials and recommendations by customers who've utilized them formerly should certainly highlight some good tradesmen.

To look for preferred experts in a few trades you may utilize a popular tradespeople testimonial web sites such as My Builder, Trustatrader, Rated People or CheckaTrade, when former customers generate testimonials and comments.

To obtain occupations, companies and tradesmen that are not listed on these types of websites, you may look at one or a couple of of these:

Top Pages, Scoot, Approved Business, Yelp, The Sun Business Directory, Opendi, Places Locally, UK Directory, Local Data Search, Britaine, Yalwa, Fyple, 2 Find Local, Near, Thomson Local, B2Index, My Local Services, City Visitor, 4ni, City Listings, Business Magnet, Touch Local, My Sheriff, City Local, 118 118, U Find Us, or other local business directories.

Are the home's windows appearing a bit mucky? Then you will definitely be searching for a quality metal polisher who you can have confidence in to take care of the work.

Choosing a tradesman using the first search results in google search on the net, will not turn out to be the correct policy, as these are in many cases not really localized metal polishers, but generally country wide metal polishing businesses.

Needless to say there has to be quite a lot of responsible polishing businesses in your area who provide a good quality service without any dilemmas.

Inquiring close to your local area, is a good option to find a decent metal polisher, testimonials and recommendations by customers who've utilized them formerly should certainly highlight some good tradesmen.

To look for preferred experts in a few trades you may utilize a popular tradespeople testimonial web sites such as My Builder, Trustatrader, Rated People or CheckaTrade, when former customers generate testimonials and comments.

To obtain occupations, companies and tradesmen that are not listed on these types of websites, you may look at one or a couple of of these:

Top Pages, Scoot, Approved Business, Yelp, The Sun Business Directory, Opendi, Places Locally, UK Directory, Local Data Search, Britaine, Yalwa, Fyple, 2 Find Local, Near, Thomson Local, B2Index, My Local Services, City Visitor, 4ni, City Listings, Business Magnet, Touch Local, My Sheriff, City Local, 118 118, U Find Us, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Hatfield include: same day polishing, trusted metal polishers, aluminium metal polishing, decorative polishing, commercial polishing, titanium polishing, industrial and commercial polishing, marine polishing, polishing machine parts, dull and satin polishing, linear metal polishing, reflective finishes, polishing copper, polishing internal bores, circle finishes, metal polishing services, motorcycle metal polishing, quality metal polishing, metal polishing motorcycle parts, polishing iron, polishing stainless steel, metal fabrication, metal polishing and finishing, polishing metals, automotive polishing, specialist angle polishing, industrial polishing, polishing alloy wheels, polishing brass, aluminium polishing, vintage polishing.

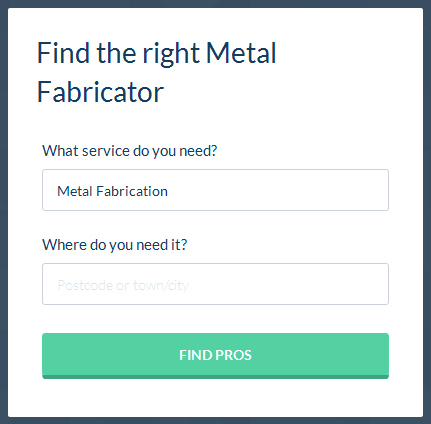

Find Hatfield Metalworkers Using Bark

| Search for a Metalworker in Hatfield |  |

Do-it-Yourself Metal Polishing Tips

An Outline of Metal Polishing - Generally, the polishing of metal is desirable for aesthetics as well as clean-room situations. It's one of the most popular practices for its use in bettering the original attractiveness of the items, as an example, cookware, motor vehicle parts or motor bike parts. Similarly, a great many clean-rooms want a polished finish so to decrease the penetrability of the material which often can result in dirt to gather and contaminate. An outstanding illustration of this usage could be in a vacuum chamber. You'll discover a lot of strategies to polish metal, and below we can focus on a little in relation to a few of the techniques involved. Various metals can be polished manually, with specialized buffing machines, electromechanically or by means of chemicals. A polishing paste or compound is frequently utilized, which may consist of aluminum oxide, tripoli, limestone, chalk, chromium oxide, dolomite, or iron oxide. Buffing stainless steel, because of its lousy thermal conductivity, its hardness, and its reasonably high viscidness is just about the time-consuming. Conversely, things made from non-ferrous metal are certainly more amenable to polishing, simply because these call for the lower number of procedures. Any time a greater processing quality is not demanded, higher pad speeds should be employed. A lesser pad speed is needed whenever a superior quality mirror finish is obligatory. Polishing buffs smothered with paste can be very much impacted by the forces on the surface of the finishing pad. The severity of the pressure on the surface might be elevated within certain guidelines, having said that, going above the most effective level of force not merely minimizes the quality level of treatment, but in addition degrades performance, could potentially cause wear to the product, and there is in addition an evident heating of the metal being worked on, due to friction. When working thin objects, it will be greater temperature (and the relating pliability of the metal) that can induce items to buckle, twist or distort. By and large, it will take a trained technician to consider each one of these variables to both avert damage to the piece and to get the project done adequately. To help you significantly boost the quality of the resultant surface area, the buffing operation really needs to be accomplished with less aggression and not as much pressure to be able to after a while deliver a surface area with no scores or marks which result from the buffing process, thus ending up with a fantastic mirror finish.

Any time a greater processing quality is not demanded, higher pad speeds should be employed. A lesser pad speed is needed whenever a superior quality mirror finish is obligatory. Polishing buffs smothered with paste can be very much impacted by the forces on the surface of the finishing pad. The severity of the pressure on the surface might be elevated within certain guidelines, having said that, going above the most effective level of force not merely minimizes the quality level of treatment, but in addition degrades performance, could potentially cause wear to the product, and there is in addition an evident heating of the metal being worked on, due to friction. When working thin objects, it will be greater temperature (and the relating pliability of the metal) that can induce items to buckle, twist or distort. By and large, it will take a trained technician to consider each one of these variables to both avert damage to the piece and to get the project done adequately. To help you significantly boost the quality of the resultant surface area, the buffing operation really needs to be accomplished with less aggression and not as much pressure to be able to after a while deliver a surface area with no scores or marks which result from the buffing process, thus ending up with a fantastic mirror finish. Also find metal polishers in: Tyttenganger, Harmer Green, Welwyn Garden City, Sandridge, Cole Green, Welham Green , North Mymms, Coopers Green, Tewin, Little Berkhamsted, Essendon, Colney Heath, Smallford and areas near to Hatfield, Hertfordshire. Maybe our reliable tips helped you to find a first-rate metal polishing company.

TOP - Specialist Odd Job Man - Rated Garden Clearance - Door Hanging - Kitchen Worktops Elgin - Door Installation Kensington - Odd Job Man Beith