Metal Polishers Harworth UK

Metal Polishers Harworth: The search for locally available metal polishers may begin on this page as you're able to conveniently utilize the convenient street map to locate a named metal polisher contained in the Harworth, Nottinghamshire area. Locate lots more metal polishers by clicking the minus control button (zoom out) button.

Harworth Metal Polishers: There are numerous approaches you can use in finding a dependable metal polisher, with telephone books, local classified ads and in addition the internet, amongst the most common. Our intention is to get metal polishers in close proximity to Harworth, Nottinghamshire.

There are different techniques you can use to locate a dependable metal polisher, with local newspapers, telephone books in addition to the internet amongst the most fashionable.

If you utilize the web for your search, solely choosing the highest metal polisher results on search engines will not quite often be the correct policy since these sometimes would possibly not turn out to be local tradespeople.

Of course there are several reputable polishing firms in your area who provide you with an excellent service without giving you any hassles.

In cases where a neighbour or perhaps local workplace has their own windows frequently maintained and cleaned, it is possible to get them to commend their particular chosen metal polishing business.

You may want to in addition access users reports and comments on a hottest trades-people's assessment websites in particular Rated People, CheckaTrade, My Builder or Trustatrader, where you could in addition be given a handful of free estimates.

To uncover providers, professions and trades not showing on this category of online websites, you could certainly check out one or several of these:

U Find Us, My Sheriff, Places Locally, BizzBuzz, The Sun Business Directory, Tipped, Yelp, 4ni, Yell, UK Directory, 2 Find Local, City Visitor, Hotfrog, Opendi, Local Data Search, My Local Services, Scoot, City Local, UK Local Search, Thomson Local, Brown Book, Wampit, City Listings, 1st Directory, Fyple, 118 118, or other local business directories.

There are different techniques you can use to locate a dependable metal polisher, with local newspapers, telephone books in addition to the internet amongst the most fashionable.

If you utilize the web for your search, solely choosing the highest metal polisher results on search engines will not quite often be the correct policy since these sometimes would possibly not turn out to be local tradespeople.

Of course there are several reputable polishing firms in your area who provide you with an excellent service without giving you any hassles.

In cases where a neighbour or perhaps local workplace has their own windows frequently maintained and cleaned, it is possible to get them to commend their particular chosen metal polishing business.

You may want to in addition access users reports and comments on a hottest trades-people's assessment websites in particular Rated People, CheckaTrade, My Builder or Trustatrader, where you could in addition be given a handful of free estimates.

To uncover providers, professions and trades not showing on this category of online websites, you could certainly check out one or several of these:

U Find Us, My Sheriff, Places Locally, BizzBuzz, The Sun Business Directory, Tipped, Yelp, 4ni, Yell, UK Directory, 2 Find Local, City Visitor, Hotfrog, Opendi, Local Data Search, My Local Services, Scoot, City Local, UK Local Search, Thomson Local, Brown Book, Wampit, City Listings, 1st Directory, Fyple, 118 118, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Harworth include: aluminium metal polishing, commercial and super bright polishing, industrial and commercial polishing, mirror polishes, marine polishing, industrial polishing, titanium polishing, dull and satin polishing, trusted metal polishers, reflective finishes, polishing engine parts, polishing machine parts, metal polishing aluminium, specialist angle polishing, metal polishing and buffing, on site polishing services, bespoke polishing, linear metal polishing, polishing brass, vintage polishing, grained finishes, polishing metals, polishing internal bores, circle finishes, quality metal polishing, polishing stainless steel, automotive polishing, metal polishing and finishing, duplex finishes, brushed finishes, same day polishing.

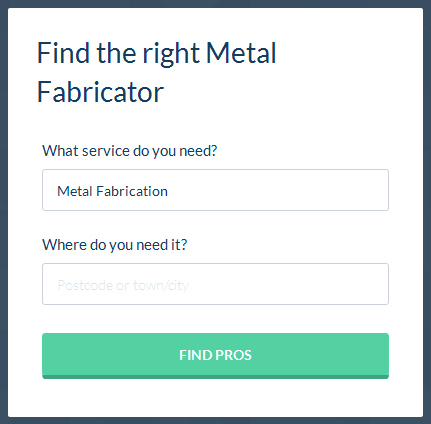

Find Harworth Metalworkers on Bark

| Pinpoint a Metalworker in Harworth |  |

Do-it-Yourself Metal Polishing Tips

A Summary of Metal Finishing - Generally, the finishing of metal is important for an attractive appearance or for clean-room usages. It really is one of the more effective techniques due to its utility in improving the overall beauty of the product, for instance, motorbike parts, cookware or vehicle parts. Furthermore, a lot of clean-rooms desire a shiny finish to decrease the permeability of the material that could cause dust to build up and contaminate. An outstanding instance of this application might be in a vacuum chamber. You'll discover a good number of approaches to finish metals, and below I will discuss a bit pertaining to the various processes required. Various metals can be finished manually, using special buffing machines, electromechanically or chemically. A special buffing paste or compound is regularly utilized, that may consist of dolomite, limestone, tripoli, aluminum oxide, chromium oxide, chalk, or iron oxide. Finishing stainless steel, due to its below average thermal conductivity, relatively high viscosity, and hardness is just about the time intensive. However, products made out of non-ferrous metal tend to be more amenable to finishing, since these need the lowest number of procedures. When a high processing quality isn't required, swifter pad speeds may be employed. A slower pad speed is utilized when a good quality mirror finish is demanded. Polishing buffs daubed in compound will be noticeably impacted by specific force on the polishing pad. The level of the surface pressure can be amplified within certain limitations, however applying in excess of the ideal amount of force not merely lowers the quality level of the procedure, but in addition decreases the level of effectiveness, might result in wear to the component, and there is moreover an evident heating up of the work-pieces, resulting from friction. When polishing thinner items, it is raised heat (and the resultant bendability of the material) which can cause items to warp, flex, or bend. In general, it takes a qualified polisher to factor in all of these fundamentals to equally avert damage to the metal part and to do the job competently. To be able to appreciably increase the standard of the finished surface area, the finishing process ought to be executed with a lesser amount of power and not as much force to be able to subsequently deliver a surface area that is free of scores or fine lines coming from the finishing process, thus arriving at a lovely mirror finish.

When a high processing quality isn't required, swifter pad speeds may be employed. A slower pad speed is utilized when a good quality mirror finish is demanded. Polishing buffs daubed in compound will be noticeably impacted by specific force on the polishing pad. The level of the surface pressure can be amplified within certain limitations, however applying in excess of the ideal amount of force not merely lowers the quality level of the procedure, but in addition decreases the level of effectiveness, might result in wear to the component, and there is moreover an evident heating up of the work-pieces, resulting from friction. When polishing thinner items, it is raised heat (and the resultant bendability of the material) which can cause items to warp, flex, or bend. In general, it takes a qualified polisher to factor in all of these fundamentals to equally avert damage to the metal part and to do the job competently. To be able to appreciably increase the standard of the finished surface area, the finishing process ought to be executed with a lesser amount of power and not as much force to be able to subsequently deliver a surface area that is free of scores or fine lines coming from the finishing process, thus arriving at a lovely mirror finish. Also find metal polishers in: Wadworth, Firbeck, New Rossington, Scrooby, Tickhill Spital, Misson, Styrrup, Langold, Bircotes, Oldcotes, Stainton, Ranskill , Serlby, Tickhill, Blyth, Bawtry, Austerfield, Maltby and areas near to Harworth, Nottinghamshire. Perhaps our tips and hints helped you to identify a first-rate local metal polisher.

|

Wimborne Minster Metal Polishers |

TOP - Affordable Odd Job Man - Rated Garden Clearance - Trusted Door Hanging - Garden Clearance Loanhead - Door Installation Godstone - Odd Job Man Rochdale