Metal Polishers Hamble-le-Rice UK

Metal Polishers Hamble-le-Rice: Should you really need to find the assistance of any nearby metal polisher, you may use this webpage to determine presently referenced locally available metal polishers active in the Hamble-le-Rice, Hampshire area. Left click the pan out any time no metal polishers are visible on this map.

Hamble-le-Rice Metal Polishers: So as to get reliable experts in a number of trades you should use one of the many primary tradespeople review websites such as Trustatrader, My Builder, CheckaTrade or Rated People, Bark, when earlier homeowners provide you with reviews and reports. Our objective is to acquire metal polishers somewhere around Hamble-le-Rice, Hampshire.

There are several strategies you can use to find a suitable metal polisher, with local newspapers, telephone book plus the world wide web being the most favoured.

It is very important to discover a nearby metal polishing company, hence merely picking out the initial rankings on the search engines using your laptop, wouldn't be the right policy, since the highest search results are in many cases for country wide polishing companies.

Thank goodness, there are lots of trustworthy polishing companies in the area that can do a good job without any headaches.

Enquiring close to your local area, is an ideal approach to finding a skilled metal polishing firm, testimonies by individuals who have chosen them before should provide you with reliable companies.

It is easy to additionally look at clients ratings and testimonies on one of many main tradespeople review internet sites which include Trustatrader, My Builder, CheckaTrade or Rated People, where you'll in addition receive a number of cost-free quotations.

To obtain skillsets, occupations and specialists that are not offered on this category of internet sites, you will be able to look at one or two of these:

Local Data Search, Business Magnet, City Local, Fyple, 192, Wampit, The Sun Business Directory, 4ni, 118 118, UK Internet Directory, Touch Local, Brown Book, Britaine, BizzBuzz, Gomy, City Visitor, Near, Zettai, Places Locally, Business Directory UK, My Local Services, UK Local Search, Thomson Local, Opendi, Approved Business, Local Life, or other local business directories.

There are several strategies you can use to find a suitable metal polisher, with local newspapers, telephone book plus the world wide web being the most favoured.

It is very important to discover a nearby metal polishing company, hence merely picking out the initial rankings on the search engines using your laptop, wouldn't be the right policy, since the highest search results are in many cases for country wide polishing companies.

Thank goodness, there are lots of trustworthy polishing companies in the area that can do a good job without any headaches.

Enquiring close to your local area, is an ideal approach to finding a skilled metal polishing firm, testimonies by individuals who have chosen them before should provide you with reliable companies.

It is easy to additionally look at clients ratings and testimonies on one of many main tradespeople review internet sites which include Trustatrader, My Builder, CheckaTrade or Rated People, where you'll in addition receive a number of cost-free quotations.

To obtain skillsets, occupations and specialists that are not offered on this category of internet sites, you will be able to look at one or two of these:

Local Data Search, Business Magnet, City Local, Fyple, 192, Wampit, The Sun Business Directory, 4ni, 118 118, UK Internet Directory, Touch Local, Brown Book, Britaine, BizzBuzz, Gomy, City Visitor, Near, Zettai, Places Locally, Business Directory UK, My Local Services, UK Local Search, Thomson Local, Opendi, Approved Business, Local Life, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Hamble-le-Rice include: brushed finishes, polishing alloy wheels, on site polishing services, polishing stainless steel, polishing bronze, metal polishing motorcycle parts, polishing nickel alloys, bespoke polishing, aluminium polishing, same day polishing, commercial polishing, mirror polishes, polishing copper, vintage polishing, linear metal polishing, decorative polishing, trusted metal polishers, grained finishes, polishing engine parts, motorcycle metal polishing, metal finishing, polishing iron, polishing brass, titanium polishing, industrial polishing, automotive polishing, polishing machine parts, sheet metal polishing, duplex finishes, aluminium metal polishing, circle finishes.

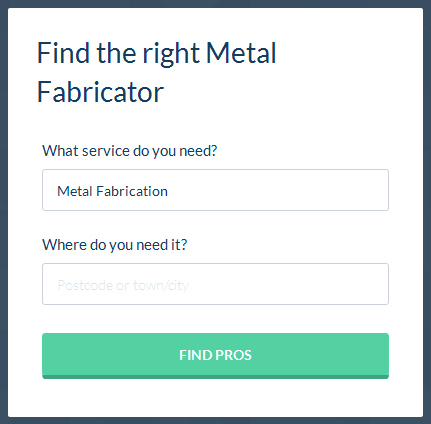

Find Hamble-le-Rice Metalworkers on Bark

| Locate a Metalworker in Hamble-le-Rice |  |

Do-it-Yourself Metal Polishing Tips

A Summary of Metal Finishing - Mostly, metal polishing is essential for aesthetic reasons and for clean-room applications. It really is one of the more favored solutions simply because of its usefulness in intensifying the overall beauty of the product, for instance, vehicle parts, cookware or motor bike parts. Besides that, plenty of clean-rooms should have a sleek finish in an effort to limit the permeability of the components which may cause debris to build up and contaminate. A good illustration of this use could be in a vacuum chamber. You'll discover plenty of means to polish metals, and let us check out a number of the steps required. Various metals may be finished manually, using special buffing machines, electromechanically or chemically. A particular polishing paste or compound is regularly put into use, that could contain dolomite, limestone, tripoli, aluminum oxide, chromium oxide, chalk, or iron oxide. Buffing stainless steel, because of its weak thermal conductivity, quite high viscidness, and hardness is just about the time intensive. More over, things built from non-ferrous metals are certainly more amenable to polishing, because these need the minimum number of operations. If a superior processing quality isn't really crucial, increased pad speeds can be utilized. A reduced pad speed is employed any time a premium quality mirror finish is imperative. Polishing buffs daubed in compound will be somewhat impacted by specific forces on the buffing pad. The level of the surface pressure might be elevated within certain ranges, but going above the optimal level of load not only lowers the quality level of the process, but additionally can degrade efficiency, could potentially cause wear on the part, and also an evident overheating of the pieces being worked on, being a result of friction. When you are working on thinner objects, it will be raised heat (and a corresponding flexibility of the metal) that may cause elements to twist, distort, or bend. In general, it takes a trained technician to factor in each one of these points to equally prevent harm to the workpiece and to give good results competently. For you to appreciably enhance the standard of the resulting finish, the polishing operation really needs to be executed with less aggression and not a large amount of pressure in order to after a while produce a surface with no scores or fine lines coming from the buffing procedure, subsequently ending up with a fantastic mirror finish.

If a superior processing quality isn't really crucial, increased pad speeds can be utilized. A reduced pad speed is employed any time a premium quality mirror finish is imperative. Polishing buffs daubed in compound will be somewhat impacted by specific forces on the buffing pad. The level of the surface pressure might be elevated within certain ranges, but going above the optimal level of load not only lowers the quality level of the process, but additionally can degrade efficiency, could potentially cause wear on the part, and also an evident overheating of the pieces being worked on, being a result of friction. When you are working on thinner objects, it will be raised heat (and a corresponding flexibility of the metal) that may cause elements to twist, distort, or bend. In general, it takes a trained technician to factor in each one of these points to equally prevent harm to the workpiece and to give good results competently. For you to appreciably enhance the standard of the resulting finish, the polishing operation really needs to be executed with less aggression and not a large amount of pressure in order to after a while produce a surface with no scores or fine lines coming from the buffing procedure, subsequently ending up with a fantastic mirror finish. Also find metal polishers in: Netley Abbey, Bursledon , Weston, Sarisbury, Hound, Old Netley, Southampton, Sholing, Swanwick, Lower Swanwick, Curbridge, Hedge End, Woolston, Botley, Burridge and areas near to Hamble-le-Rice, Hampshire. Maybe our advice helped you to come up with a good metal polishers firm.

TOP - UK Odd Job Man - Reliable Garden Clearance - Door Fitters Specialists - Kitchen Worktops Pendlebury - Door Installation Rosyth - Odd Job Man Tetbury