Metal Polishers Hadfield UK

Metal Polishers Hadfield: If you happen to attempting to find a local metal polisher, one could conveniently try the interactive map directly below for available found metal polishers active in the Hadfield, Derbyshire local area. Uncover a lot more metal polishers by simply clicking the minus navigation button (zoom out) navigation button.

Hadfield Metal Polishers: There are lots of measures you can use locating a suitable metal polisher, with local newspapers, phone book plus the web amongst the preferred. The intention is to seek out metal polishers around Hadfield, Derbyshire.

There are several methods you can use locating a reliable metal polisher, with the web, yellow pages and in addition the local classifieds, being the most favored.

Should you use the web for your search, just deciding on the initial metal polisher listings in google search would not be the right approach as these quite often would not actually be local metal polishing companies.

Fortunately, there are several respectable polishing companies close by that will do a terrific job without headaches.

Personal suggestions are obviously the best way to find the best metal polisher, and so question someone that you know who ordinarily utilizes metal polishers.

So as to get reliable experts in a number of trades you may use one of the leading tradesmen's referral sites in particular Trustatrader, My Builder, CheckaTrade or Rated People, when past clientele make available testimonials and critiques.

To discover companies, tradesmen and professions not included on this category of sites, you could possibly look at one or a number of of these:

Fyple, Yalwa, Gomy, 2 Find Local, The Sun Business Directory, Yell, Tipped, My Local Services, UK Internet Directory, UK Directory, 1st Directory, Yelp, Local Life, Free Index, 4ni, City Listings, Business Directory UK, Hotfrog, Local Data Search, Opendi, Britaine, 118 118, Top Pages, Approved Business, 192, UK Local Search, or other local business directories.

There are several methods you can use locating a reliable metal polisher, with the web, yellow pages and in addition the local classifieds, being the most favored.

Should you use the web for your search, just deciding on the initial metal polisher listings in google search would not be the right approach as these quite often would not actually be local metal polishing companies.

Fortunately, there are several respectable polishing companies close by that will do a terrific job without headaches.

Personal suggestions are obviously the best way to find the best metal polisher, and so question someone that you know who ordinarily utilizes metal polishers.

So as to get reliable experts in a number of trades you may use one of the leading tradesmen's referral sites in particular Trustatrader, My Builder, CheckaTrade or Rated People, when past clientele make available testimonials and critiques.

To discover companies, tradesmen and professions not included on this category of sites, you could possibly look at one or a number of of these:

Fyple, Yalwa, Gomy, 2 Find Local, The Sun Business Directory, Yell, Tipped, My Local Services, UK Internet Directory, UK Directory, 1st Directory, Yelp, Local Life, Free Index, 4ni, City Listings, Business Directory UK, Hotfrog, Local Data Search, Opendi, Britaine, 118 118, Top Pages, Approved Business, 192, UK Local Search, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Hadfield include: special finishes, polishing alloy wheels, polishing internal bores, polishing copper, industrial and commercial polishing, mirror polishes, polishing bronze, linear metal polishing, marine polishing, same day polishing, polishing machine parts, metal finishing, quality metal polishing, duplex finishes, decorative polishing, metal polishing motorcycle parts, metal polishing and buffing, commercial polishing, metal polishing and finishing, trusted metal polishers, automotive polishing, metal polishing services, sheet metal polishing, metal polishing aluminium, polishing nickel alloys, grained finishes, polishing brass, reflective finishes, bespoke polishing, motorcycle metal polishing, metal fabrication.

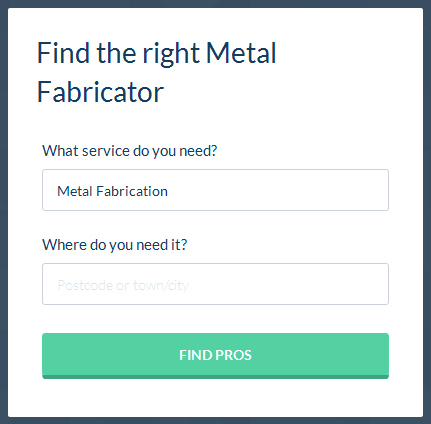

Find Hadfield Metalworkers on Bark

| Identify a Metalworker in Hadfield |  |

Do-it-Yourself Metal Polishing Tips

Novices Guide to Metal Polishing - Typically, metal finishing is wanted for aesthetics and for clean-room applications. It is among the most favored processes because of its utility in maximizing the overall beauty of the item, for instance, vehicle parts, kitchenware or motor bike parts. Moreover, many clean-rooms will want a shiny finish so as to reduce the penetrability of the metal surfaces which can result in dust to gather and contaminate. An excellent instance of this usage could be in vacuum chambers. There exist several means to finish metals, and we'll look into several of the methods required. Various metals may be polished by hand, using purpose made buffing machines, electromechanically or chemically. A particular finishing paste or compound is regularly put into use, which may include aluminum oxide, limestone, chromium oxide, tripoli, chalk, dolomite, or iron oxide. Polishing stainless steel, due to its inferior thermal conductivity, its hardness, and its relatively high viscidity is among the most time-consuming. Conversely, products built from non-ferrous metals are definitely more receptive to polishing, since they need the least number of operations. Any time a greater processing quality is not necessary, faster pad speeds could be used. A decreased pad speed is needed if a quality mirror finish is mandatory. Polishing buffs bedaubed with compound can be markedly affected by the force on the polishing pad. The level of the surface pressure might be raised to a specified extent, though going over the optimal measure of force not just reduces the quality level of treatment, but also can worsen efficiency, can result in wear to the part, plus there is also an evident overheating of the pieces being worked on, an outcome of friction. When you are using thin metal, it will be greater heat (and the resultant flexibility of the metal) that can cause components to warp, bend or flex. Usually, it will take an experienced polisher to take into consideration each one of these fundamentals to both avoid harm to the part and to get the work done adequately. In order to radically enhance the standard of the resultant finish, the buffing process needs to be performed with significantly less vigour and not a large amount of pressure in an effort to finally complete a surface that doesn't have any scratches or marks left behind by the polishing procedure, subsequently arriving at a lovely mirror finish.

Any time a greater processing quality is not necessary, faster pad speeds could be used. A decreased pad speed is needed if a quality mirror finish is mandatory. Polishing buffs bedaubed with compound can be markedly affected by the force on the polishing pad. The level of the surface pressure might be raised to a specified extent, though going over the optimal measure of force not just reduces the quality level of treatment, but also can worsen efficiency, can result in wear to the part, plus there is also an evident overheating of the pieces being worked on, an outcome of friction. When you are using thin metal, it will be greater heat (and the resultant flexibility of the metal) that can cause components to warp, bend or flex. Usually, it will take an experienced polisher to take into consideration each one of these fundamentals to both avoid harm to the part and to get the work done adequately. In order to radically enhance the standard of the resultant finish, the buffing process needs to be performed with significantly less vigour and not a large amount of pressure in an effort to finally complete a surface that doesn't have any scratches or marks left behind by the polishing procedure, subsequently arriving at a lovely mirror finish. Also find metal polishers in: Broadbottom, Hollingworth, Mottram in Longdendale, Charlesworth, Tintwistle, Chisworth, Brookfield, Hyde, Padfield, Glossop, Staleybridge, Gamesley, Millbrook, Compstall , Carrbrook and areas near to Hadfield, Derbyshire. Most likely our hints helped you to unearth a decent metal polisher.

|

Cambridgeshire Metal Polishers |

TOP - Specialist Odd Job Man - Low-Cost Garden Clearance - Door Fitters Professionals - Garden Clearance Winstanley - Door Installation Westerham - Odd Job Man Langley Mill