Metal Polishers Diss UK

Metal Polishers Diss: Your quest for local metal polishers can start below because you can very easily make use of the practical road map to find a listed metal polisher included in the Diss, Norfolk area. In the event that there aren't any metal polishers visible on our map, click on the minus (zoom out) button.

Diss Metal Polishers: There are several strategies you can employ in finding a respectable metal polisher, with the internet, phone book and the local classified ads, amongst the most widely used. You after all are trying to find metal polishers around Diss, Norfolk.

There are many strategies you can use in finding a good quality metal polisher, with telephone books, local papers as well as the online world, among the most fashionable.

Deciding on a polishing company by using the first listings in the search engines on the world wide web, might not be the right policy, because these are sometimes not really localized metal polishers, but usually countrywide businesses.

Quality metal polishing enterprises though, will never be that tough to uncover, you should quickly be able to discover one in the area.

Asking people in your neighbourhood, is an efficient approach to find an experienced metal polishing business, testimonies by people who have used them in the past ought to provide reliable firms.

For getting preferred experts in a few skills feel free to use one of the many foremost tradesmen assessment websites including Trustatrader, Rated People, CheckaTrade or My Builder, whereby former clientele generate ratings and feedback.

When checking out facilities, professions and trades not specified on these types of internet sites, you should try one or a few of these:

UK Local Search, Fyple, BizzBuzz, City Listings, Hotfrog, Tipped, B2Index, My Sheriff, 4ni, 1st Directory, Top Pages, Business Magnet, 118 118, Gomy, Places Locally, Brown Book, 2 Find Local, UK Internet Directory, The Sun Business Directory, Yell, Scoot, City Visitor, Thomson Local, Opendi, Local Life, Near, or other local business directories.

There are many strategies you can use in finding a good quality metal polisher, with telephone books, local papers as well as the online world, among the most fashionable.

Deciding on a polishing company by using the first listings in the search engines on the world wide web, might not be the right policy, because these are sometimes not really localized metal polishers, but usually countrywide businesses.

Quality metal polishing enterprises though, will never be that tough to uncover, you should quickly be able to discover one in the area.

Asking people in your neighbourhood, is an efficient approach to find an experienced metal polishing business, testimonies by people who have used them in the past ought to provide reliable firms.

For getting preferred experts in a few skills feel free to use one of the many foremost tradesmen assessment websites including Trustatrader, Rated People, CheckaTrade or My Builder, whereby former clientele generate ratings and feedback.

When checking out facilities, professions and trades not specified on these types of internet sites, you should try one or a few of these:

UK Local Search, Fyple, BizzBuzz, City Listings, Hotfrog, Tipped, B2Index, My Sheriff, 4ni, 1st Directory, Top Pages, Business Magnet, 118 118, Gomy, Places Locally, Brown Book, 2 Find Local, UK Internet Directory, The Sun Business Directory, Yell, Scoot, City Visitor, Thomson Local, Opendi, Local Life, Near, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Diss include: circle finishes, metal fabrication, same day polishing, dull and satin polishing, industrial and commercial polishing, automotive polishing, mirror polishes, metal polishing and buffing, special finishes, metal polishing aluminium, polishing nickel alloys, duplex finishes, motorcycle metal polishing, aluminium polishing, titanium polishing, on site polishing services, polishing bronze, reflective finishes, brushed finishes, polishing copper, sheet metal polishing, linear metal polishing, metal finishing, polishing metals, marine polishing, decorative polishing, custom metal polishing, polishing brass, industrial polishing, bespoke polishing, metal polishing services.

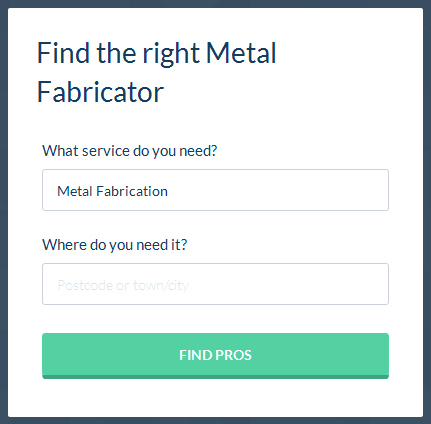

Find Diss Metalworkers at Bark

| Pinpoint a Metalworker in Diss |  |

Do-it-Yourself Metal Polishing Tips

A Summary of Metal Polishing - Most frequently, the finishing of metal is required for aesthetic reasons and for clean-room usage. It is one of the most accepted procedures because of its utility in improving the natural beauty of the product, such as, motor bike parts, kitchenware or auto parts. Also, many clean-rooms must have a shiny finish in order to lower the permeability of the material which might result in dust to build up and contaminate. An outstanding illustration of this use would be in a vacuum chamber. You'll discover many approaches to polish metals, and we can think about the various techniques involved. Metals may be finished electromechanically, utilizing chemicals, manually by hand, or with specialized buffing machines. A special buffing compound or paste is normally applied, which could incorporate limestone, aluminum oxide, dolomite, chalk, chromium oxide, tripoli, or iron oxide. Polishing stainless steel, because of its inferior thermal conductivity, its hardness, and its fairly high viscidity is typically one of the most time intensive. Alternatively, items fabricated from non-ferrous metal are usually more amenable to finishing, mainly because these demand the least number of processes. Any time a superior processing quality is not mandatory, swifter pad speeds can be utilised. A slower pad speed is used if a good quality mirror finish is demanded. Polishing buffs bedaubed in compound are seriously affected by specific force on the surface of the pad. The concentration of the pressure on the surface might be elevated to a precise scope, but implementing beyond the ideal level of force not just cuts down on the quality of the procedure, but also can worsen effectiveness, can bring about wear to the component, and there's moreover an apparent overheating of the work-pieces, attributable to friction. When you are working on thin items, it's higher temperature (and a relating flexibility of the metal) that can cause materials to twist, buckle or distort. Basically, it needs a competent polisher to add in each one of these variables to equally not cause damage to the workpiece and to operate proficiently. To help appreciably increase the quality of the resultant surface, the polishing process should be performed with not as much vigour and not so much force so as to in time complete a surface that is free of scratches or marks which result from the polishing process, thus arriving at a fantastic mirror finish.

Any time a superior processing quality is not mandatory, swifter pad speeds can be utilised. A slower pad speed is used if a good quality mirror finish is demanded. Polishing buffs bedaubed in compound are seriously affected by specific force on the surface of the pad. The concentration of the pressure on the surface might be elevated to a precise scope, but implementing beyond the ideal level of force not just cuts down on the quality of the procedure, but also can worsen effectiveness, can bring about wear to the component, and there's moreover an apparent overheating of the work-pieces, attributable to friction. When you are working on thin items, it's higher temperature (and a relating flexibility of the metal) that can cause materials to twist, buckle or distort. Basically, it needs a competent polisher to add in each one of these variables to equally not cause damage to the workpiece and to operate proficiently. To help appreciably increase the quality of the resultant surface, the polishing process should be performed with not as much vigour and not so much force so as to in time complete a surface that is free of scratches or marks which result from the polishing process, thus arriving at a fantastic mirror finish. Also find metal polishers in: Roydon, Winfarthing, Thelveton, Botesdale, Brome, Burston, Dickleburgh , Shimpling, Hoxne, Bressingham, Gissing, Stuston, Shelfanger, Scole, Thrandeston, Palgrave and areas near to Diss, Norfolk. Perhaps our hints helped you to identify a first-rate metal polishing specialist.

TOP - Affordable Odd Job Man - Reviewed Garden Clearance - Door Fitters Professionals - Kitchen Worktops Birstall - Door Installation Dundee - Odd Job Man Rawmarsh