Metal Polishers Dalton UK

Metal Polishers Dalton: The search for neighbourhood metal polishers should commence below because you can effectively employ our handy map to locate a listed metal polisher within the Dalton, South Yorkshire area. Any time no metal polishers display on our map, hit the zoom out button.

Dalton Metal Polishers: Happily, you'll find numerous efficient polishing enterprises in your area that will do a fantastic job without any hassles. You obviously are looking to get metal polishers close to Dalton, South Yorkshire.

There are lots of techniques you can use to find a good metal polisher, with the world wide web, telephone book in addition to the local newspapers, amongst the most widely used.

Make sure that you search for a nearby metal polishing business, which means simply selecting the first listings in search engines using your laptop, will not be the correct approach, since those top rankings are in many cases for national businesses.

Fortuitously, there are numerous dependable metal polishing companies nearby who'll do a good quality job without headaches.

Where a neighbour or even local business building has their own windows frequently cleaned, you'll be able to encourage them to endorse their particular preferred metal polishing firm.

It's possible to also view customers testimonials and comments on one of several best tradesmen's referral internet sites such as Trustatrader, My Builder, CheckaTrade or Rated People, where you may even obtain a number of free quotes.

With regards to businesses, tradesmen and facilities not registered on these types of internet sites, you could certainly consider one or a number of of these:

Local Life, 1st Directory, Top Pages, Yalwa, 2 Find Local, Thomson Local, City Local, Places Locally, Scoot, Approved Business, Tipped, City Visitor, Yelp, Free Index, UK Local Search, Brown Book, 4ni, 192, 118 118, City Listings, My Sheriff, Touch Local, Near, UK Internet Directory, Wahanda, Opendi, or other local business directories.

There are lots of techniques you can use to find a good metal polisher, with the world wide web, telephone book in addition to the local newspapers, amongst the most widely used.

Make sure that you search for a nearby metal polishing business, which means simply selecting the first listings in search engines using your laptop, will not be the correct approach, since those top rankings are in many cases for national businesses.

Fortuitously, there are numerous dependable metal polishing companies nearby who'll do a good quality job without headaches.

Where a neighbour or even local business building has their own windows frequently cleaned, you'll be able to encourage them to endorse their particular preferred metal polishing firm.

It's possible to also view customers testimonials and comments on one of several best tradesmen's referral internet sites such as Trustatrader, My Builder, CheckaTrade or Rated People, where you may even obtain a number of free quotes.

With regards to businesses, tradesmen and facilities not registered on these types of internet sites, you could certainly consider one or a number of of these:

Local Life, 1st Directory, Top Pages, Yalwa, 2 Find Local, Thomson Local, City Local, Places Locally, Scoot, Approved Business, Tipped, City Visitor, Yelp, Free Index, UK Local Search, Brown Book, 4ni, 192, 118 118, City Listings, My Sheriff, Touch Local, Near, UK Internet Directory, Wahanda, Opendi, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Dalton include: dull and satin polishing, vintage polishing, polishing metals, metal polishing motorcycle parts, quality metal polishing, metal polishing aluminium, decorative polishing, aluminium metal polishing, sheet metal polishing, polishing brass, polishing alloy wheels, commercial and super bright polishing, mirror polishes, industrial polishing, specialist angle polishing, motorcycle metal polishing, polishing copper, reflective finishes, titanium polishing, custom metal polishing, marine polishing, duplex finishes, brushed finishes, commercial polishing, metal polishing and buffing, automotive polishing, circle finishes, aluminium polishing, polishing iron, metal polishing and finishing, special finishes.

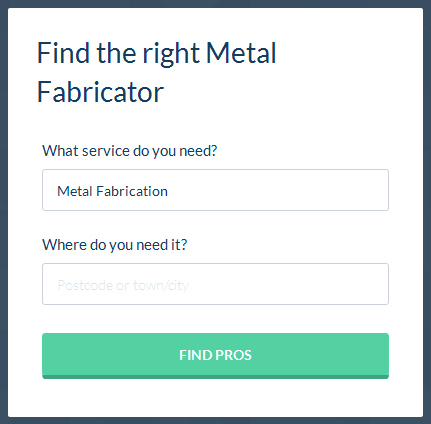

Find Dalton Metalworkers Using Bark

| Find a Metalworker in Dalton |  |

Do-it-Yourself Metal Polishing Tips

The Basics of Metal Polishing - Nearly always, the polishing of metal is essential for aesthetics as well as clean-room applications. It really is one of the most widely used solutions due to its usefulness in boosting the natural beauty of the items, as an example, motor bike parts, cookware or automobile parts. Equally, numerous clean-rooms demand a polished finish so as to minimize the penetrability of the material which can cause particles to collect and contaminate. An outstanding illustration of this application could be in vacuum chambers. There exist plenty of ways to finish metal, and we'll have a look at a few of the techniques required. Metal may be finished electromechanically, chemically, manually by hand, or with specialized buffing machines. A polishing compound or paste may be used, that might consist of tripoli, dolomite, limestone, chalk, aluminum oxide, chromium oxide, or iron oxide. Polishing stainless steel, due to its substandard thermal conductivity, its hardness, and its comparatively high viscidity is commonly one of the most time-consuming. More over, merchandise built from non-ferrous metals are definitely more responsive to polishing, since they demand the lower number of procedures. Where a greater processing quality is not demanded, higher pad speeds should be considered. A lesser pad speed is applied in the event that a high quality mirror finish is requested. Finishing buffs daubed with paste will be markedly impacted by specific pressures on the surface of the pad. The level of the surface pressure might be raised to a specified range, although further surpassing the most effective level of load not only cuts down the quality of the process, but additionally degrades performance, can create wear on the part, and there is also an apparent overheating of the objects being worked on, because of friction. When polishing thinner items, it will be raised temperature (and a relating bendability of the metal) that causes components to flex, bend or warp. In general, it needs an experienced technician to take into consideration every one of these things to equally not cause harm to the piece and to work proficiently. To help substantially enhance the standard of the resulting surface area, the buffing action needs to be performed with a lot less vigour and not a large amount of pressure to be able to finally deliver a surface area that is free of scores or fine lines brought about by the polishing procedure, thereby ending up with a fantastic mirror finish.

Where a greater processing quality is not demanded, higher pad speeds should be considered. A lesser pad speed is applied in the event that a high quality mirror finish is requested. Finishing buffs daubed with paste will be markedly impacted by specific pressures on the surface of the pad. The level of the surface pressure might be raised to a specified range, although further surpassing the most effective level of load not only cuts down the quality of the process, but additionally degrades performance, can create wear on the part, and there is also an apparent overheating of the objects being worked on, because of friction. When polishing thinner items, it will be raised temperature (and a relating bendability of the metal) that causes components to flex, bend or warp. In general, it needs an experienced technician to take into consideration every one of these things to equally not cause harm to the piece and to work proficiently. To help substantially enhance the standard of the resulting surface area, the buffing action needs to be performed with a lot less vigour and not a large amount of pressure to be able to finally deliver a surface area that is free of scores or fine lines brought about by the polishing procedure, thereby ending up with a fantastic mirror finish. Also find metal polishers in: Bramley, Ravenfield, Hill Top, Micklebring, Thrybergh, Eastwood, Morthen , Rotherham, Wickersley, Hooton Roberts, Kilnhurst, Rawmarsh, Flanderwell, Greasbrough, Sunnyside and areas near to Dalton, South Yorkshire. Perhaps our helpful hints helped you to get hold of a quality metal polishing contractor.

TOP - Trustworthy Odd Job Man - Inexpensive Garden Clearance - Door Fitters Quotations - Kitchen Worktops Kidderminster - Door Installation East Leake - Odd Job Man Eaglescliffe