Metal Polishers Dalry UK

Metal Polishers Dalry: If you happen to hunting for a nearby metal polisher, you should effortlessly employ the interactive map on this page to discover presently referenced metal polishers active in the Dalry, Scotland local area. If none display, get nearest metal polishers by just hitting the zoom out button.

Dalry Metal Polishers: If you utilize the online world for the search, quickly picking out the first metal polisher rankings in google search might not in fact be the correct option since these often might not actually be local metal polishing businesses. Your goal is to identify metal polishers in the vicinity of Dalry, Scotland.

Are your home windows seeming rather grimy? Then you're going to be looking for a respectable metal polisher who you can rely upon to deal with the work.

Selecting a tradesman by using the highest results in an internet search engine on the net, will most likely not in many cases be the right strategy, as these are in many cases not really local metal polishers, but usually nationwide metal polishing businesses.

Undoubtedly there must be lots of honest polishing companies close by who deliver a fantastic service with no complications.

Personal testimonials and recommendations are not surprisingly the optimal approach to find a professional metal polisher, hence ask anybody you know who normally makes use of these types of services.

You might furthermore acquire free estimates and look at past users reviews and feedback on one of the primary trades-people's recommendation sites for example CheckaTrade, Bark, My Builder, Rated People or Trustatrader.

Regarding tradesmen, providers and professions not itemized on this category of sites, you ought to try one or two of these:

Scoot, 1st Directory, Fyple, 2 Find Local, Tipped, Zettai, Approved Business, Business Magnet, U Find Us, Wampit, 192, 4ni, The Sun Business Directory, Local Data Search, My Local Services, City Listings, UK Local Search, City Visitor, Hotfrog, Gomy, 118 118, Business Directory UK, BizzBuzz, Thomson Local, Opendi, Yelp, or other local business directories.

Are your home windows seeming rather grimy? Then you're going to be looking for a respectable metal polisher who you can rely upon to deal with the work.

Selecting a tradesman by using the highest results in an internet search engine on the net, will most likely not in many cases be the right strategy, as these are in many cases not really local metal polishers, but usually nationwide metal polishing businesses.

Undoubtedly there must be lots of honest polishing companies close by who deliver a fantastic service with no complications.

Personal testimonials and recommendations are not surprisingly the optimal approach to find a professional metal polisher, hence ask anybody you know who normally makes use of these types of services.

You might furthermore acquire free estimates and look at past users reviews and feedback on one of the primary trades-people's recommendation sites for example CheckaTrade, Bark, My Builder, Rated People or Trustatrader.

Regarding tradesmen, providers and professions not itemized on this category of sites, you ought to try one or two of these:

Scoot, 1st Directory, Fyple, 2 Find Local, Tipped, Zettai, Approved Business, Business Magnet, U Find Us, Wampit, 192, 4ni, The Sun Business Directory, Local Data Search, My Local Services, City Listings, UK Local Search, City Visitor, Hotfrog, Gomy, 118 118, Business Directory UK, BizzBuzz, Thomson Local, Opendi, Yelp, or other local business directories.

Video - Metal Polishing Tips For Beginners - How To Restore and Polish Metal Surfaces:

Metal Polishers services available in Dalry include: polishing stainless steel, grained finishes, polishing nickel alloys, polishing internal bores, decorative polishing, bespoke polishing, metal polishing services, industrial polishing, polishing alloy wheels, specialist angle polishing, metal polishing motorcycle parts, industrial and commercial polishing, linear metal polishing, aluminium polishing, metal polishing and buffing, on site polishing services, metal fabrication, special finishes, motorcycle metal polishing, sheet metal polishing, quality metal polishing, trusted metal polishers, polishing brass, circle finishes, same day polishing, commercial polishing, aluminium metal polishing, dull and satin polishing, polishing bronze, brushed finishes, metal polishing and finishing.

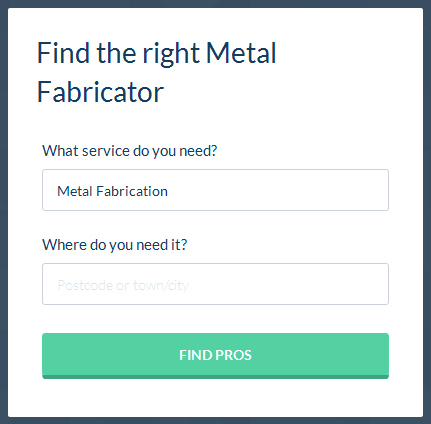

Find Dalry Metalworkers on Bark

| Find a Metalworker in Dalry |  |

Do-it-Yourself Metal Polishing Tips

Learners Guide to Metal Polishing - Mostly, metal finishing is necessary for appearance or for clean-room applications. It's one of the more prominent techniques because of its utility in intensifying the original attractiveness of the item, for instance, kitchenware, automobile parts or motorbike parts. Additionally, a good number of clean-rooms really need a burnished finish in an effort to limit the permeability of the components which can cause dirt to gather and contaminate. An outstanding example of this implementation could be in a vacuum chamber. There exist loads of different ways to polish metals, and we will think about a few of the procedures involved. Metal can be burnished electromechanically, chemically, manually by hand, or with specialized buffing machines. A special finishing paste or compound is routinely used, that might contain chalk, chromium oxide, limestone, aluminum oxide, dolomite, tripoli, or iron oxide. Finishing stainless steel, because of its substandard thermal conductivity, rather high viscosity, and hardness is considered the most time-consuming. On the other hand, things built from non-ferrous metals are usually more responsive to buffing, because they call for the lowest number of treatments. Where a high processing quality isn't called for, quicker pad speeds may be employed. A slower pad speed is used when a superior quality mirror finish is called for. Polishing buffs plastered with paste are greatly impacted by the force on the pad. The concentration of the surface pressure may be increased to a specific range, although employing beyond the perfect level of load not just decreases the quality level of treatment, but also worsens performance, might lead to wear on the product, and in addition an obvious heating of the items being worked on, on account of friction. With thin items, it is greater temperature (and the relating pliancy of the metal) that can induce items to flex, twist or bend. In general, it needs a proficient polisher to factor in each one of these fundamentals to both prevent damage to the piece and to operate competently. To be able to appreciably increase the quality of the final surface, the polishing operation is required to be performed with not as much power and not a large amount of pressure so that you may ultimately complete a surface without scores or marks caused by the buffing process, thus arriving at a fabulous mirror finish.

Where a high processing quality isn't called for, quicker pad speeds may be employed. A slower pad speed is used when a superior quality mirror finish is called for. Polishing buffs plastered with paste are greatly impacted by the force on the pad. The concentration of the surface pressure may be increased to a specific range, although employing beyond the perfect level of load not just decreases the quality level of treatment, but also worsens performance, might lead to wear on the product, and in addition an obvious heating of the items being worked on, on account of friction. With thin items, it is greater temperature (and the relating pliancy of the metal) that can induce items to flex, twist or bend. In general, it needs a proficient polisher to factor in each one of these fundamentals to both prevent damage to the piece and to operate competently. To be able to appreciably increase the quality of the final surface, the polishing operation is required to be performed with not as much power and not a large amount of pressure so that you may ultimately complete a surface without scores or marks caused by the buffing process, thus arriving at a fabulous mirror finish. Also find metal polishers in: Braehead, Glengarnock , Dunlop, Lugton, Beith, Drakemyre, Highfield, Kilwinning, Barrmill, Kilbirnie, Woodside, Lochwinnoch, Largs, Uplawmoor, West Kilbride, Gateside, Stewarton and areas near to Dalry, Scotland. Maybe our tricks helped you to unearth a reputable metal polishers company.

TOP - Specialist Odd Job Man - Trusted Garden Clearance - Trustworthy Door Hanging - Garden Clearance Southbourne - Door Installation Kendal - Odd Job Man Middlewich